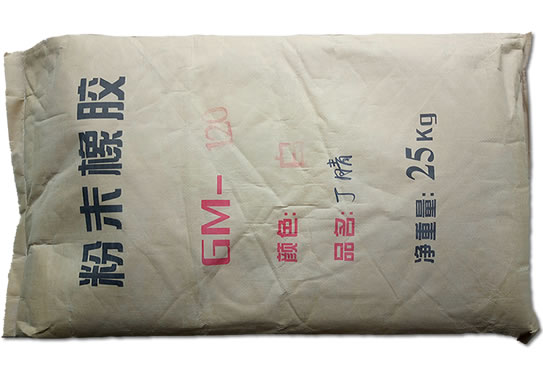

With the continuous improvement of people's awareness of environmental protection and the importance of resource recycling, powder nitrile reclaimed rubber powder as a new material has gradually become a hot topic in the field of rubber modification. As a polar acrylonitrile and butadiene copolymer, powdered nitrile reclaimed rubber powder has many excellent properties and can be widely used in the production of various plastic materials. It can be used as an additive for plastic materials such as PVC, thermoplastic elastomer TPR, and TPE, TPV and other thermoplastic elastomer modifiers, epoxy resin, phenolic resin toughened and wear-resistant production friction materials, increase the elasticity, impact resistance, toughness, aging resistance, weather resistance, oil resistance, low temperature brittleness.

Powder nitrile regeneration rubber powder can also be used as a modifier for organic synthetic materials such as epoxy resin and phenolic resin. Because butadiene rubber has excellent heat, cold, oil, corrosion and aging resistance, it can significantly improve the performance and quality of these organic synthetic materials. Powder nitrile reclaimed rubber powder can obtain raw materials by recycling waste rubber products, and obtained after high-temperature processing, crushing and other processes. Therefore, the use of butadiene recycled rubber powder for rubber modification can not only improve the performance of the material, but also help to recycle waste. The use of powdered nitrile regenerated rubber powder has the following advantages:

The polar properties of nitrile recycled rubber powders are very compatible with plastic materials and resins. Therefore, nitrile recycled rubber powder is widely used in the shoe industry, hoses, wires and cables, conveyor belts, profiles, friction materials and other engineering resins modification; By adding nitrile recycled rubber powder, the elasticity, impact resistance, toughness, aging resistance, weather resistance, oil resistance, low temperature brittleness resistance of the product can be improved, and the quality and service life of the product can be improved.

The application of nitrile recycled rubber powder can also reduce energy consumption in the production process and improve production efficiency. Compared with traditional bulk nitrile rubber, the use of powder nitrile rubber can provide a better degree of mixing, reduce the power consumption of the mixing process, save time, improve efficiency and reduce wage expenses, and the powder nitrile reclaimed rubber powder used in the rubber products industry can increase productivity by 50% compared to products produced with block nitrile.

We carried out a series of experiments to verify the application effect of nitrile regenerated rubber powder in rubber modification, and compared the experimental data after modification by adding 10-30% of the total amount of powder nitrile regenerated rubber powder: adding an appropriate amount of nitrile regenerated rubber powder can significantly improve the performance of rubber products. For example, adding nitrile recycled rubber powder to shoe materials can improve the wear resistance and slip resistance of the sole, and improve the service life of the sole; In hose manufacturing, the addition of nitrile recycled rubber powder can improve the pressure resistance and corrosion resistance of the hose and improve the safety of the hose. Friction block After the production enterprise uses nitrile regenerated rubber powder, the product quality is significantly improved, the customer satisfaction is significantly improved, and the cost is reduced by more than 20% compared with the use of nitrile raw rubber; After the use of nitrile recycled rubber powder by shoe material enterprises, the wear resistance and slip resistance of shoes have been significantly improved, the cost of raw materials has been reduced by 13%, and the market competitiveness of products has also improved.

Nitrile regenerated rubber powder has broad application prospects in rubber modification, and by adding nitrile regenerated rubber powder, product performance can be improved, production power consumption and wage expenditure can be reduced, and production efficiency can be improved. With the increasing awareness of environmental protection and the importance of resource recycling, it is believed that nitrile recycled rubber powder will play a more important role in the field of rubber modification.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits