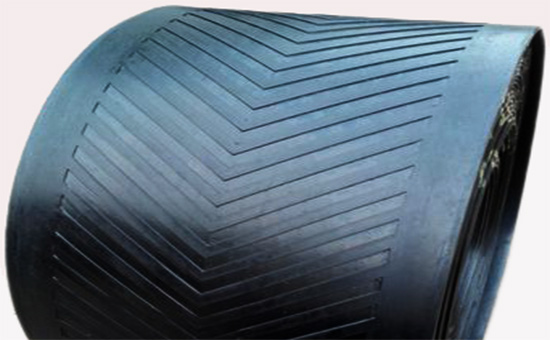

During the activation process, the molecular chain of the rubber powder is destroyed, and new active groups are formed on the surface, thereby improving its compatibility and adhesion with the matrix glue. Ordinary conveyor belt covering rubber requires rubber to have high tensile strength, wear resistance, tear resistance, aging resistance and good viscosity, generally processed with natural rubber, styrene-butadiene rubber, butadiene rubber, etc. as the main raw materials, and the appropriate amount of filling activated rubber powder can effectively reduce the cost of raw materials.

1. Ordinary conveyor belt covering glue is mixed with activated rubber powder vulcanization formula

60 parts of natural rubber, 40 parts of butadiene rubber, 40 parts of activated rubber powder, 5.7 parts of zinc oxide, 4.3 parts of stearic acid, 1.4 parts of paraffin, 0.7 parts of antioxidant A, 2.1 parts of antioxidant 4010, 32 parts of mixed carbon black, 40 parts of super wear-resistant carbon black, 23 parts of solid coumerone, 2.6 parts of sulfur, 2.6 parts of accelerator CZ; Total: 254.4 shares.

The tensile strength of vulcanized rubber is 20MPa, the elongation at break is 560%, the constant tensile stress of 300% is 8MPa, and the hardness of Shore is 60 degrees.

2. The change law of physical and mechanical properties of ordinary conveyor belt covering rubber mixed with activated rubber powder

Compared with vulcanized rubber powder, the compatibility among activated rubber powder and Matrigel is better. In the appropriate amount of activated rubber powder in the conveyor belt covering rubber formula, the formula is appropriately adjusted, and the tensile strength, tearing elongation and hardness of the conveyor belt covering rubber are basically the same as those of the rubber without rubber powder, the elasticity has decreased, and the 300% constant tensile stress has been significantly improved.

3. Ordinary conveyor belt covering rubber formula design skills mixed with activated rubber powder

When natural rubber/butadiene rubber is mixed with activated rubber powder to prepare rubber conveyor belt covering rubber, the glue content of the formula is generally controlled at about 50%; Appropriate adjustment of the formula, especially the vulcanization system, the reinforcing filling system and the softening and plasticizing system, can further improve the finished product index of conveyor belt covering rubber.

(1) Vulcanization system: choose the traditional sulfur vulcanization system, and appropriately increase the amount of sulfur to promote the vulcanization reaction and ensure the cross-linking density of the rubber compound. Commonly used accelerators include accelerators M, DM and after-acting accelerators CZ and NOBS.

(2) Reinforcing filling system: high wear-resistant carbon black and semi-reinforcing carbon black are selected to reinforce the rubber material with good tensile properties, wear resistance and tear resistance; Semi-reinforcing carbon black has good dispersion and fluidity, which can evenly distribute the functional molecules in the rubber, making the rubber easier to process.

(3) Softening plasticizing system: commonly used softening plasticizer engine oil, heavy oil, aromatic oil, pine tar, coumaron resin, petroleum resin, etc.

The use of activated rubber powder in ordinary conveyor belt covering rubber can not only effectively reduce production costs, but also improve the mechanical properties E4LYY417 processing performance of rubber compounds through reasonable formula design and process adjustment. In actual production, when the conveyor belt covering rubber in different use occasions is mixed with rubber powder, the proportion of various components in the formula should be adjusted at any time according to the specific application requirements and performance indicators, so as to achieve the best balance among physical properties and economic benefits.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits