In all kinds of vehicles, vehicles, machinery, hydraulic transmission, chemical pipelines, instrumentation and other fields are inseparable from rubber sealing products, mechanical devices can prevent the leakage of fluid media in static or moving state, and prevent external dust, sediment And other impurities into the sealing mechanism, play a good sealing effect. Natural rubber is an important raw material for the production of rubber sealing products; latex reclaimed rubber, as a low-cost raw material to replace natural rubber, can be used in combination with natural rubber or other rubbers to produce various sealing products; rationally design the formulation of sealing products containing natural reclaimed rubber, which can be found in Effectively reduce the cost of raw materials on the premise of maintaining product quality.

1. The physical properties of latex reclaimed rubber and its main applications in rubber sealing products

Latex reclaimed rubber has the basic performance characteristics of natural rubber, high mechanical strength, good elasticity, wear resistance, tear resistance, suitable for vegetable oil, alcohol, water and the use of n-butanol and castor oil brake fluid, but not resistant to mineral oil, not suitable for Use in hot air. Latex reclaimed rubber can be used alone or in combination with natural rubber and general synthetic rubber to produce brake cups, aprons, rubber sealing strips, heat-resistant gaskets, gaskets, etc.

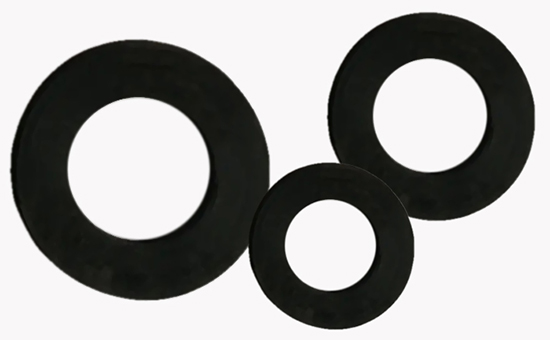

In actual production, black latex reclaimed rubber can be used to produce black and dark rubber sealing products, and the cost is lower; white latex reclaimed rubber can be used to produce light-colored and colored rubber sealing products, which are easy to color and not easy to change color.

2. Formula design principles of rubber sealing products containing latex reclaimed rubber

When designing the formula of rubber sealing products, the formula should be designed according to the product performance requirements, product structure and production process. The designed formula should meet the processing technology requirements, and the formula should be adjusted through performance tests to meet the needs of industrial production. When designing the formula of rubber sealing products, it is also necessary to consider the source of raw materials, etc., under the premise of ensuring product performance, use cheap materials as much as possible to reduce costs.

3. Key points of formula design of common rubber sealing products containing latex reclaimed rubber

(1) Latex reclaimed rubber to produce rubber O-rings

Rubber O-rings require good tensile properties, constant elongation strength, and low compression set. The rubber used for dynamic O-rings also needs to have excellent wear resistance.

When using latex reclaimed rubber to prepare O-rings, the vulcanization system is recommended to use a low-pressure vulcanization system, such as peroxide, low sulfur and high acceleration, etc., to improve the compression set resistance of the rubber compound. High hardness products can use multifunctional compounds as DCP co-crosslinking agent. High hardness rubber is generally reinforced with carbon black with small particle size, high structure and good reinforcing effect. If necessary, high wear-resistant carbon black, channel carbon black and fast extrusion carbon black can be used together to prepare small compression deformation. , High hardness rubber compound with good wear resistance and large elongation. Low molecular polyethylene can be used as processing aid to improve the heat generation, scorch and extrusion properties during the processing of high-hardness and medium-hardness compounds.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits