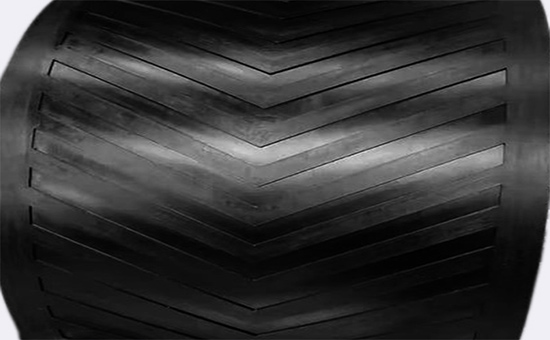

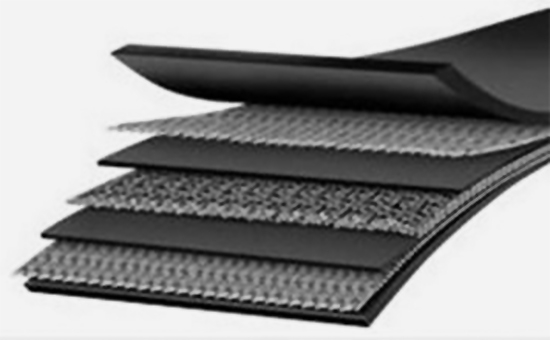

Rubber conveyor belts can be divided into ordinary conveyor belts, special conveyor belts, flame-retardant conveyor belts, steel wire rope conveyor belts, etc. according to their uses. The rubber materials used for each component of ordinary conveyor belts include cover rubber, buffer rubber, cloth layer rubbing glue, and cloth layer glue. Four kinds, generally processed from natural rubber as the main raw material. The latex reclaimed rubber is mixed into the production of each rubber layer of the ordinary conveyor belt covering rubber, and the rational design of the vulcanization system can further optimize the comprehensive performance of the ordinary conveyor belt containing the latex reclaimed rubber.

1. Design of vulcanization system for ordinary conveyor belt covering rubber in the production of latex reclaimed rubber

Ordinary conveyor belt covering rubber needs to withstand various aging effects such as impact, wear and microbial corrosion of materials, and requires high tensile strength, wear resistance, aging resistance, tear resistance, and biological erosion resistance. Latex reclaimed rubber 2ELYY729 When preparing ordinary conveyor belt covering rubber, the vulcanization system mostly adopts sulfur-accelerator combination system, and the accelerator is generally used together with M and DM; accelerators CZ, NOBS, etc. can be used in the conveyor belt covering rubber containing styrene-butadiene rubber Aftereffect accelerator.

2. Design of vulcanization system for ordinary conveyor belt buffer rubber in the production of latex reclaimed rubber

Ordinary conveyor belt buffer glue can increase the adhesion among the cover rubber and the belt core layer, absorb and disperse the impact force of the conveyed material, and play a buffering role. Conveyor belt buffer glue requires good adhesiveness (adhesion among glue and cloth 78.5N/5cm), high elasticity, low heat generation, good heat dissipation and good process performance. Latex reclaimed rubber is generally used in combination with natural rubber and butadiene rubber to prepare conveyor belt buffer rubber; low-sulfur compounding is recommended for the vulcanization system, in order to improve the adhesion among the rubber layer and the cloth layer; M, DM, TMTD are commonly used as accelerators; It is recommended to use after-effect accelerators such as CZ and NOBS for the buffer rubber containing styrene-butadiene rubber.

3. Design of vulcanization system for ordinary conveyor belt wiping rubber in the production of latex reclaimed rubber

Ordinary conveyor belt wiping glue is the cloth layer wiping glue, the main function is to bond the canvas layer with the core into a whole; it is required to have good adhesion to the core material (the adhesion strength of the cloth to the cloth is not less than 78.5N/m), Fatigue resistance (the number of flexures of the cloth layer should exceed 25,000 times/full peeling), and it must have sufficient plasticity (plasticity 0.5-0.6) and process properties such as scorch resistance. When using latex reclaimed rubber to produce ordinary conveyor belt covering rubber cloth, it is recommended to use a sulfur-accelerator system for the vulcanization system. The accelerator is generally used together with accelerators M and DM, or a small amount of TMTD is added to speed up the vulcanization rate, but pay attention to prevent The glue is scorched.

When using latex reclaimed rubber to produce each rubber layer of ordinary rubber conveyor belts, it is necessary to select a suitable vulcanization system, and appropriately adjust the amount of vulcanizing agent and accelerator in the vulcanization system. , the amount of sulfur should be less than the amount of sulfur in latex reclaimed rubber or natural rubber/latex reclaimed rubber combined. Later, the editor will continue to share with you the key points of compounding agents in the production of ordinary conveyor belts using latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits