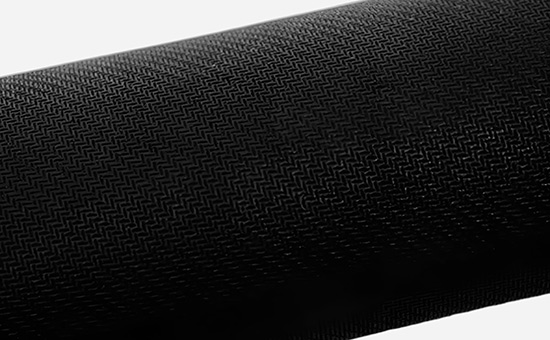

Mouse pad sponge glue is used at the bottom of the mouse pad, by using the elasticity, anti-slip and cushioning of rubber to provide stable support for the mouse, requiring the rubber to have good elasticity, wear resistance, etc., mostly using natural rubber, butadiene rubber, styrene-butadiene rubber as the main material. Latex reclaimed rubber is a recycled rubber product made of waste natural rubber, waste latex and its products through crushing, desulfurization, filtration and other processes, with the basic performance characteristics of natural rubber, which can be used alone or in combination with natural rubber to produce mouse pad sponge glue.

1. Application skills of latex reclaimed rubber in mouse pad sponge glue

(1)Latex reclaimed rubber choice tips

It is recommended to choose a latex reclaimed rubber E4LYY1213 with good elasticity, low ash content, no impurities, environmental protection and no taste, and directly cooperate with a regular reclaimed rubber factory of a certain scale to avoid rough surface or vulcanization defects caused by Impurities in latex reclaimed rubber, or unqualified quality of mouse pad sponge glue due to the fluctuation of latex reclaimed rubber quality.

From the cost aspect, since the sponge glue of the mouse pad is basically black, it is recommended to choose black natural latex reclaimed rubber, which is lower than the white latex reclaimed rubber of the same index and more cost-effective.

(2) Latex reclaimed rubber mixing skills

The effective rubber hydrocarbon content of reclaimed rubber is an important factor in determining the proportion of natural rubber that it replaces with natural rubber. For example, when the effective rubber hydrocarbon content of latex reclaimed rubber is 75%, 100 parts of latex reclaimed rubber can replace 75 parts of natural rubber. When using natural reclaimed rubber in natural rubber mouse pad sponge glue to reduce costs, it is necessary to reasonably determine the mixing ratio of latex reclaimed rubber according to the performance requirements of mouse pad sponge glue and the specific indicators of latex reclaimed rubber, which is generally among 10% and 50%.

2. Mouse pad sponge glue mixed with latex reclaimed rubber vulcanization formula design points

(1) Latex reclaimed rubber production mouse pad sponge glue formula design

To design a mouse pad sponge glue formula containing latex reclaimed rubber, it is important to balance the vulcanization rate and the decomposition rate of the foaming agent to avoid uneven hole size or excessive thickness of the surface adhesive layer. The vulcanization system is generally dominated by sulfur, and the vulcanization rate is coordinated with accelerators CZ and TMTD. Foaming agent H is used in conjunction with baking soda to enhance the effect of opening pores.

(2) Practical formula for latex reclaimed rubber to produce mouse pad sponge glue

80 parts of natural rubber, 20 parts of latex reclaimed rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of antioxidant D, 1 part of antioxidant 4010, 15 parts of conductive carbon black, 40 parts of ointment, 1.5 parts of accelerator CZ, 0.35 parts of accelerator TMTD, 2.65 parts of sulfur, 8.5 parts of foaming agent H, 15 parts of baking soda; 192 in total.

When using latex reclaimed rubber to reduce the production cost of sponge rubber for natural rubber mouse pads, it is necessary to select appropriate latex reclaimed rubber according to the specific needs of sponge glue, reasonably determine the proportion of reclaimed rubber mixture, appropriately adjust the rubber formula and production process, and further optimize the comprehensive indicators of mouse pads while reducing costs; In the future, Xiaobian will continue to share with you the production process and precautions of latex reclaimed rubber production mouse pad sponge glue.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits