Natural latex recycled rubber is processed from waste natural rubber and waste latex products as raw materials, with the characteristics of high tensile strength, good elasticity and high elongation at break, which can replace all or part of natural rubber to produce various white rubber products, effectively reducing the cost of raw materials. When producing white rubber products with latex recycled rubber, natural rubber/latex recycled rubber and glue, the following issues need to be paid attention to.

1. Option skills of latex recycled rubber for white rubber products

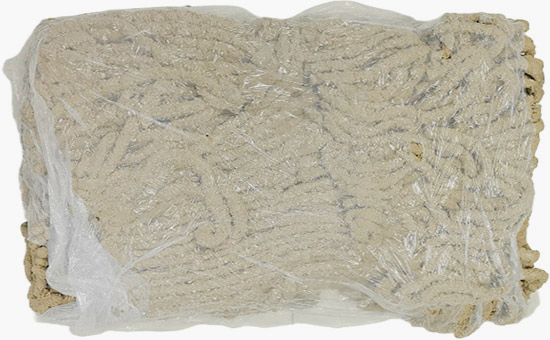

Use latex recycled rubber for white rubber products, use white or light-colored latex recycled rubber, chosen high-purity, less impurities, and non-migration recycled rubber products to avoid impurities affecting the color uniformity of white products and ensure the color stability of the finished product.

2. Key points of formula design for the production of white rubber products from latex recycled rubber

(1) Vulcanization system

It is recommended to choose a vulcanization system that does not affect the color (such as the sulfur-accelerator CZ system), and avoid using vulcanizing agents with too high sulfur content or easy discoloration. Control the amount of sulfur E5LYY77 and accelerator to avoid excessive discoloration or performance degradation of products; White latex recycled rubber products (such as white rubber soles) with high color requirements can be choosed with sulfur-free vulcanizing agents, such as DCP; For latex recycled rubber products with high elasticity requirements, it is recommended to use a low-sulfur and high-promotion system.

(2) Reinforce the filling system

When using latex recycled rubber as the main raw material to produce white rubber products, it is recommended to use white or light-colored reinforcing agents and fillers, such as silica, activated calcium carbonate, magnesium carbonate, etc., and be cautious about using black rubber reinforcing fillers, especially carbon black.

(3) Soften the system

It is recommended to use colorless or light-colored softeners such as paraffin oil and naphthenic oil for the softening system of white latex recycled rubber products, and avoid using dark softeners such as aromatic oil and pine tar to further improve the plasticity and fluidity of the compound.

(4) Anti-aging system

add light-colored anti-aging agents to delay the aging and discoloration of white latex recycled rubber products; Add antioxidants or UV absorbers if necessary.

3. Key points of the production process of white rubber products produced by latex recycled rubber

(1) Pretreatment of compounds: paraffin, stearic acid and other compounds are crushed, screened, dried and other treatments before use to ensure that there are no impurities and moisture.

(2) Key points of the mixing process: It is recommended to adopt a gradual feeding method, first add recycled glue and softener, and then add filler and vulcanizing agent; Ensure that the compound is evenly dispersed and avoid local overheating affecting color and performance.

(3) Key points of vulcanization process: determine the vulcanization temperature and time according to the formula and product requirements of white latex recycled rubber products; strictly control the vulcanization parameters to avoid oversulfur or undersulfur affecting the performance and color stability of the product; Avoid contact among the rubber material and contaminants during molding and keep the mold clean.

Reasonable design of the formula of white rubber products containing latex recycled rubber can further reduce the cost of raw materials under the premise of ensuring the quality of the finished product, and then share with you the vulcanization formula of latex recycled rubber to produce white rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits