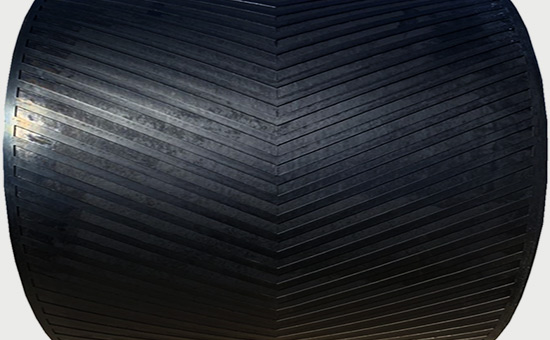

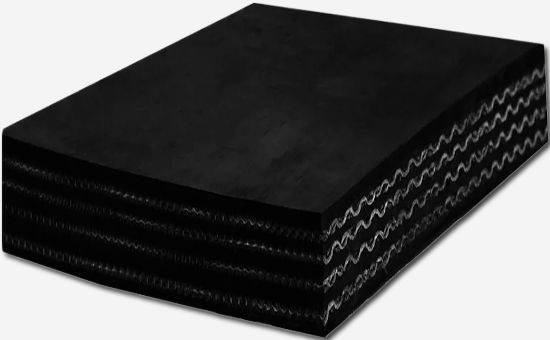

The ordinary fabric core conveyor belt has the characteristics of high strength and large bearing capacity. It is mainly used to transport non corrosive materials at room temperature. The conveyor belt covering rubber directly contacts with materials and is exposed to the external environment. It is generally processed with natural rubber as the main raw material. However, the price of natural rubber is high and fluctuates greatly. Many manufacturers of ordinary fabric core conveyor belts begin to use recycled rubber in the covering rubber of conveyor belts. How much recycled rubber is appropriate to be mixed in the covering rubber?

In actual production, the covering rubber of ordinary fabric core conveyor belt needs to withstand various aging effects such as material impact, wear, microbial erosion, etc. when the conveyor belt is working. It is required to have good tensile strength, wear resistance, tear resistance and aging resistance. Natural rubber is mainly used, or an appropriate amount of styrene butadiene rubber and cis-1,4-polybutadiene rubber are used. The overall rubber content is generally controlled among 50% and 55%.

1. Practical reference formula for producing ordinary fabric core conveyor belt covering rubber by mixing 10 parts of recycled rubber

60 shares of natural rubber, 40 shares of styrene butadiene rubber, 10 shares of recycled rubber, 5 shares of zinc oxide, 2 shares of stearic acid, 1 share of antioxidant A, 1 share of antioxidant D, 1 share of paraffin wax, 18 shares of carbon black N 330, 32 shares of mixed carbon black, 6 shares of engine oil, 10 shares of coumarone resin, 5 shares of asphalt, 1 share of accelerator DM, 0.15 shares of promoter TMTD, 0.6 shares of accelerator D, 2.1 shares of sulfur; Total: 194.85 copies.

2. The practical reference formula for the production of ordinary fabric core conveyor belt covering rubber by mixing 30 parts of recycled rubber

75 natural rubber, 25 polybutadiene rubber, 30 reclaimed rubber, 4.5 zinc oxide, 3 stearic acid, 1 antioxidant A, 1 antioxidant D, 2 paraffin wax, 48 carbon black N330, 15 engine oil, 0.8 accelerator M, 1 accelerator CZ, 2 sulfur; Total: 208.3 copies.

3. The practical reference formula for the production of ordinary fabric core conveyor belt covering rubber by mixing 100 parts of recycled rubber

60 natural rubber, 40 polybutadiene rubber, 100 reclaimed rubber, 5 zinc oxide, 3 stearic acid, 1 antioxidant A, 1 antioxidant D, 60 carbon black N330, 45 active calcium carbonate, 1 paraffin, 5 pine tar, 1.2 accelerator DM, 0.4 accelerator D, 4.5 sulfur; Total: 327.1 copies.

When using recycled rubber in the production of ordinary fabric core conveyor belt with natural rubber as the main raw material to reduce costs, rubber product manufacturers need to reasonably mix recycled rubber 2ELYY1014 according to the requirements of various technical indicators of the conveyor belt, especially the tensile strength, elongation at break, hardness and other indicators. For example, when preparing fabric core conveyor belt covering rubber with tensile strength of about 19MPa, the amount of recycled rubber is generally controlled among 10-30 phr; When covering rubber is produced for fabric core conveyor belt with tensile strength below 14MPa, the amount of recycled rubber can be increased to more than 100 phr.

In actual production, the mixing amount of recycled rubber in the covering rubber of ordinary fabric core conveyor belt of natural rubber is also related to the type of recycled rubber. For example, the high strength pure latex recycled rubber can replace natural rubber with a ratio of 1:1, while 100 parts of tire recycled rubber can replace about 30 parts of raw rubber. Later, Xiaobian will continue to share with you the ideal mixing amount and mixing skills of recycled rubber in each rubber layer of natural rubber production rubber conveyor belt.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits