Natural rubber is the most widely used general rubber in the rubber product industry at present. It has the characteristics of high mechanical strength, good elasticity, good processing performance, and can be used with most synthetic rubber. However, the price of natural rubber is high and fluctuates greatly, so many manufacturers of natural rubber products begin to use recycled rubber in rubber products with natural rubber as the main raw material. Which recycled rubber can be mixed with natural rubber? What are the specific functions? Which rubber products can be produced by blending natural rubber/recycled rubber?

1. Combination of natural rubber and latex reclaimed rubber

The main raw materials of reclaimed latex include waste rubber cups and rubber wires of natural rubber, waste rubber coagulated by latex products factory, waste natural rubber, waste latex products such as latex finger condoms, condoms, etc., which are made through classification, crushing, desulfurization, refining and other processes. The natural reclaimed rubber has the basic performance characteristics of natural rubber. It has high strength, good elasticity and high elongation at break. The hydrocarbon content of high-quality pure latex reclaimed rubber can reach more than 75%. It can directly replace natural rubber or be used with natural rubber to produce rubber products, reducing costs.

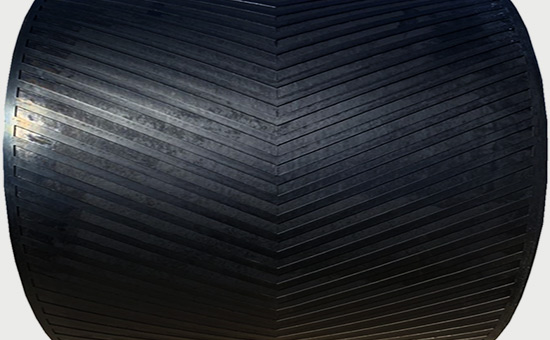

In actual production, natural rubber can be used together with latex reclaimed rubber to produce tire sheaths, rubber soles, rubber hoses, tape, rubber plates, wire and cable sheaths, V-belts, conveyor belts, rubber pads, sealing strips and other products, effectively reducing the cost of raw materials, saving labor and electricity. The manufacturer of natural rubber products can select appropriate recycled latex according to the color of rubber products, including white recycled latex, black recycled latex, and colored (red and green) recycled latex.

2. Combination of natural rubber and recycled tire rubber

The main raw materials of recycled tire rubber are waste automobile tires. The main components are natural rubber, general synthetic rubber and carbon black. It has good compatibility with natural rubber and its price is much lower than that of natural rubber. Therefore, natural rubber products can be used together with 2ELYY1117, a suitable proportion of recycled tire rubber. For example, 5-10 parts of recycled tire rubber are mixed in the tread rubber of automobile tires, so the driving distance of tires is longer. The recycled tire rubber mainly includes the recycled tire tread rubber (Qiangligao), superfine recycled tire rubber (high fineness), environment-friendly recycled tire rubber (environment-friendly), tasteless recycled tire rubber, etc.

In actual production, natural rubber can be used together with tire recycled rubber to produce high wear resistant rubber products such as automobile tire outer tubes, conveyor belts, V-belts, rubber plates, rubber pads, shoes and other environment-friendly odorless natural rubber products, as well as rubber tubes, rubber strips, wire and cable sheaths, bladder, inner tubes, seals, coating rubber, waterproof materials, etc.

3. Combination of natural rubber and butyl reclaimed rubber

Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, and its compatibility with other rubbers is better than that of butyl rubber. Therefore, butyl reclaimed rubber can be appropriately mixed with some natural rubber products to further improve the air tightness and heat resistance of natural rubber products while reducing costs. In actual production, a small amount of butyl reclaimed rubber can be used when producing rubber products such as rubber inner tube and bladder with natural rubber as the main raw material; The natural rubber can also be used with butyl reclaimed rubber to produce the tire cushion belt, etc., to improve the overall flex cracking resistance and tear resistance of the cushion belt.

4. Combination of natural rubber and other recycled rubber

In actual production, natural rubber can also be used together with isoprene reclaimed rubber, styrene butadiene reclaimed rubber, cis-1,4-polybutadiene reclaimed rubber, chlorinated butyl reclaimed rubber, nitrile reclaimed rubber, etc., which can reduce the raw material cost of rubber products and improve the rubber processing performance; For example, natural rubber is prone to reversion of vulcanization, which can be significantly improved when mixed with recycled rubber. Later, Xiaobian will continue to share with you the vulcanization formula and production process points of natural rubber and recycled rubber for various rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits