Sub-brand and other natural rubber refers to natural rubber that cannot be used normally due to deterioration, moisture, aging and other reasons in the process of processing, transportation and storage. Sub-brand and other external natural rubber occupies a large proportion in China's rubber industry, and a large number of sub-brand and other external natural rubber are produced every year. The recycling of natural rubber such as sub-brands is an important part of the development of China's rubber industry, and it is also an important way to save resources and protect the environment.

The production of black high-elastic shock-absorbing rubber pads from sub-brand and other natural rubber has the following low-cost advantages:

(1) The price of natural rubber is low. The price of sub-brand and other external natural rubber is generally about 1/3 of the new natural rubber, so the use of sub-brand and other external natural rubber to produce black high-elastic shock-absorbing rubber pads can reduce production costs.

(2) There are a wide range of sources of natural rubber such as sub-plates. Sub-brand and other external natural rubber occupies a large proportion in China's rubber industry, and a large number of sub-brand and other external natural rubber are produced every year. Therefore, there are a wide range of sources of external natural rubber such as sub-brand, which can meet the demand for the production of black high-elastic shock-absorbing rubber pads.

(3) The processing technology of external natural rubber such as sub-brand is simple. The processing technology of sub-brand and other external natural rubber is simple and does not require complex equipment and technology, so it can reduce production costs.

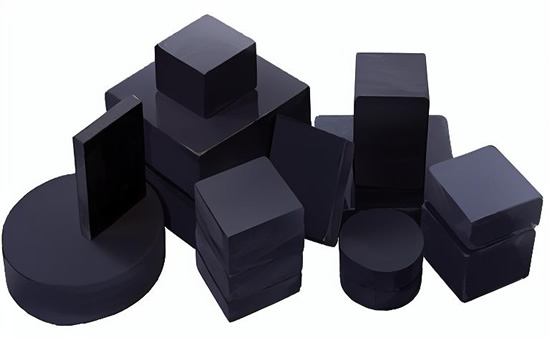

(4) The black high-elastic shock-absorbing rubber mat produced by the sub-brand and other natural rubber has good performance. The black high-elastic shock-absorbing rubber mat produced by the sub-brand and other external natural rubber has good elasticity, abrasion resistance, corrosion resistance and aging resistance, so it can meet the needs of various uses.

There are many ways to recycle natural rubber outside the sub-brand, including physical method, chemical method, biological method, etc. The physical method is to use the physical properties of natural rubber such as sub-brands for recycling, mainly including crushing, separation, pyrolysis, carbonization and other methods. The chemical method is to use the chemical properties of natural rubber such as sub-brand for recycling, mainly including solvent extraction, thermal cracking, oxidation and other methods. The biological method is to use the action of microorganisms to recycle natural rubber such as sub-brand, mainly including fermentation, composting and other methods.

The production of black high-elastic shock-absorbing rubber pads by sub-brand and other natural rubber has the advantage of low cost. The price of sub-brand and other external natural rubber is low, the source is wide, the processing technology is simple, and the production of black high-elasticity shock-absorbing rubber pads has good performance. Therefore, the production of black high-elastic shock-absorbing rubber pads by sub-brand and other external natural rubber has broad market prospects.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits