Sub-brand styrene-butadiene rubber is styrene-butadiene rubber production process due to process fluctuations, raw material impurities, equipment failure and other factors produced not to meet the genuine quality standards, has a certain use value of the rubber, the chemical structure and genuine styrene-butadiene rubber is basically the same, the price is much lower, can be used alone or with genuine styrene-butadiene rubber, natural rubber, butadiene rubber, etc.

1. Key points of the design of the vulcanization system of the sub-brand styrene-butadiene rubber products

The vulcanization system mainly includes vulcanizing agents, accelerators and active agents. When using sub-brand styrene-butadiene rubber as the main raw material in the production of rubber products, the commonly used vulcanizing agents include sulfur, sulfur donors and organic peroxides.

Sulfur is the most commonly used vulcanizing agent for sub-brand styrene-butadiene rubber products, the dosage is generally 1.5-2.0 parts; appropriately increasing the dosage of sulfur can improve the tensile strength, tensile stress and wear resistance of vulcanized rubber, but the tear strength and elongation of the vulcanized rubber of sub-brand styrene-butadiene rubber become poor, the hardness becomes larger, the elasticity decreases, and the heat resistance, aging resistance and flexural resistance are poor. When the sub-brand styrene-butadiene rubber is vulcanized with peroxide, the amount of peroxide (such as DCP) is controlled among 1.5-2 parts; with the increase of the dosage and activity of carbon black, the dosage of peroxide should be appropriately increased, and the tensile strength, tear strength and elongation of peroxide vulcanized rubber material alone are low, and the combined use of active agents (such as S, TAIC, HVA2, etc.) can obtain better comprehensive properties.

The accelerators commonly used in the production of sub-brand styrene-butadiene rubber products include accelerators DM, M, NOBS, CZ, etc., in the case of a large number of filled with high wear-resistant carbon black, the dosage of sulfur is 1.75-2 parts, and the accelerator CZ can be used with sulfur, and the dosage is controlled at 0.3~1.2 parts. The active agents commonly used in sub-brand styrene-butadiene rubber products are zinc oxide and stearic acid; The dosage of zinc oxide is among 3-5 parts and the dosage of stearic acid is among 1.5-2.5.

2. Key points of the design of the reinforcement filling system of sub-brand styrene-butadiene rubber products

In the production of sub-brand styrene-butadiene rubber products, it is necessary to use reinforcing agents and fillers to endow vulcanized rubber with good mechanical properties, and the most commonly used reinforcing agent is carbon black, with a dosage of among 30-60; When sub-brand styrene-butadiene rubber is used to produce light-colored rubber products, silica can be used for reinforcement, or activated calcium carbonate can be used; In order to further reduce the production cost of sub-brand styrene-butadiene rubber products, calcium carbonate, clay, clay, rubber powder, etc. can be filled, and the filling amount is recommended to be controlled below 200 copies. The use of acidic fillers such as silica, clay, etc., requires an appropriate amount of ethylene glycol, ethylene glycol, triethanolamine, polyethylene glycol ester active agents, and the dosage is generally among 5% and 10% of the filler amount.

3. Key points of design of softening system for sub-brand styrene-butadiene rubber products

The sub-brand styrene-butadiene rubber retains the basic structure of styrene-butadiene rubber, with high intermolecular resistance and poor fluidity, and the appropriate use of softeners and plasticizers can effectively improve the processing performance of rubber compounds. The commonly used softeners and plasticizers for sub-brand styrene-butadiene rubber products include coumaron resin, pine tar and petroleum-based operating oil.

In the sub-brand styrene-butadiene rubber, Coumeron resin can not only improve the dispersion of the compounding agent and the smooth rolling and pressing of the accelerator, but also have a certain reinforcing effect to improve the tensile performance and wear resistance of the vulcanized rubber E5LYY113; It should be noted that the resin of Coumaron is viscous, and it is easy to stick to the roller if the amount is used too much. The dosage of softener and plasticizer in sub-brand styrene-butadiene rubber products needs to be determined according to the physical property requirements such as the dosage of carbon black and filler, hardness and process performance requirements.

4. Key points of the design of the anti-aging system of sub-brand styrene-butadiene rubber products

The sub-brand styrene-butadiene rubber has better heat-and-oxygen aging resistance than natural rubber, and has a certain protective effect, and the antioxidant used is basically the same as that of natural rubber. Ozone-resistant rubber products can use antioxidants 4010, 4010NA, AW, 3100, and light-colored sub-brand styrene-butadiene rubber products need to choose non-polluting antioxidants antioxidants MB, SP-C, 264, 2246, etc.

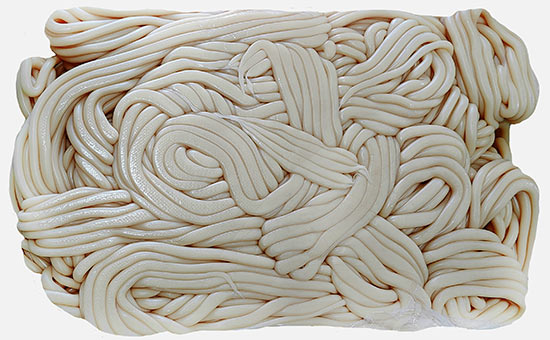

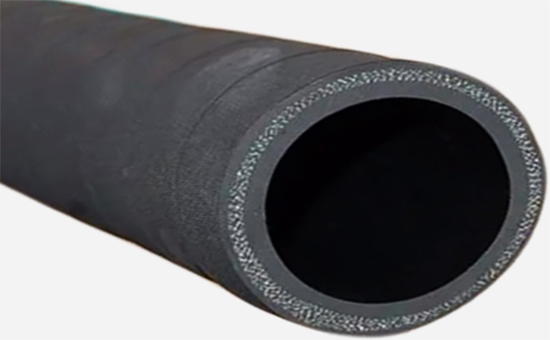

The second brand styrene-butadiene rubber 1502 (block) is light yellow odorless rubber in appearance, with excellent heat resistance, weather resistance, chemical stability, aging resistance and tear resistance. The performance index is basically the same as that of genuine styrene-butadiene rubber, which can be used in combination with styrene-butadiene rubber to reduce costs, and can also replace 50% styrene-butadiene rubber or natural rubber 1:1. It has a wide range of applications in asphalt modification, plastic modification, and rubber products. Applicable products: rubber belts, rubber pipes, wire and cable sheaths, tire and inner tubes, auto parts, rubber V-belts, rubber seals, rubber soles, rubber special-shaped miscellaneous parts, etc.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits