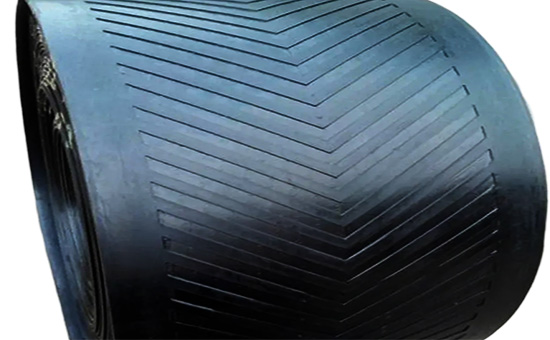

Heat resistant conveyor belt requires that the rubber material has excellent heat resistance. It is not easy to age and crack when used at a high temperature for a long time. It is generally made of neoprene, styrene butadiene rubber, butyl rubber, ethylene propylene rubber, etc. The reclaimed butyl rubber retains the basic performance characteristics of butyl rubber and has good heat resistance. It can directly replace the original butyl rubber or be used with EPDM to produce heat-resistant conveyor belts. A reasonable formula design can effectively reduce the cost on the premise of ensuring the service performance and life of heat-resistant conveyor belts.

1. Vulcanization system design of heat-resistant conveyor belt for butyl reclaimed rubber production

When butyl reclaimed rubber is used in heat-resistant conveyor belt to reduce cost, sulfur free compounding, peroxide and resin curing system are used for curing, and the heat resistance of vulcanizate is better. The thermal decomposition temperature of butyl rubber vulcanized with resin is 250-300 ℃. The heat-resistant conveyor belt with EPDM as the main raw material is usually vulcanized with low sulfur compounding or peroxide (commonly used DCP). When blending butyl reclaimed rubber, it is necessary to comprehensively consider the characteristics of the two rubber compounds, properly adjust the curing system, and sulfur curing system can be used.

2. Reinforcing system design of heat-resistant conveyor belt for butyl reclaimed rubber production

When using butyl reclaimed rubber to prepare heat-resistant conveyor belt, high wear-resistant carbon black such as N330 and air mixed carbon black are commonly used, and the amount is controlled 40-50 phr. Properly increasing the amount of carbon black can increase the hardness of rubber and prevent the conveyor belt from cracking at high temperature. In actual production, inorganic fillers are more heat-resistant than carbon black. Inorganic fillers beneficial to the heat resistance of conveyor belt include white carbon black, active zinc oxide, magnesium oxide, aluminum oxide, silicate, etc.

3. Softening system design of heat-resistant conveyor belt for butyl reclaimed rubber production

Heat resistant rubber conveyor belt has three requirements for softener: stable under high temperature, low volatility, and softening point higher than the use temperature; Common softeners used in the preparation of heat resistant rubber include coal tar, petroleum resin, chlorinated paraffin, solid coumarone, etc. When using butyl reclaimed rubber 2ELYY109 to produce heat-resistant conveyor belt, it is recommended to use Gumarone resin, or use Vaseline, paraffin oil, mineral rubber and petroleum asphalt together; Naphthenic oil and paraffin oil can be selected as softeners when butyl reclaimed rubber is mixed in ethylene propylene rubber heat-resistant conveyor belt.

In the formulation of heat-resistant conveyor belt containing butyl reclaimed rubber, several softeners and plasticizers are used together to further improve the viscosity and heat resistance of the rubber compound.

4. Anti aging system design of heat-resistant conveyor belt for butyl reclaimed rubber production

The protective effect of amine antioxidant in butyl rubber is not obvious, and phenol antioxidant is commonly used. When butyl reclaimed rubber is used in heat-resistant rubber conveyor belt, it is recommended to use antioxidant 2246, antioxidant MB, etc. to improve the heat-resistant aging performance of butyl heat-resistant conveyor belt.

When using butyl reclaimed rubber to reduce the production cost of heat-resistant conveyor belt, the rubber product manufacturer must reasonably design the formula to reduce more costs on the premise of ensuring the use performance of the conveyor belt. Later, Xiaobian will continue to share with you the mixing and vulcanization techniques for producing heat-resistant conveyor belt with butyl reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits