Industrial rubber products are rubber products used in the industrial field, which generally require rubber materials to have good elasticity, wear resistance, oil resistance, chemical corrosion resistance, insulation, sealing and shock absorption. Butyl reclaimed rubber retains the excellent air tightness of butyl rubber and good heat resistance, water resistance and aging resistance, and can be used with butyl rubber in appropriate proportions to produce industrial rubber products, such as sealing gaskets, shock absorbing blocks, anti-corrosion linings, etc.

1. Butyl reclaimed rubber produces rubber sealing gaskets

Butyl reclaimed rubber has good heat resistance, water resistance and aging resistance, and is an ideal raw material for replacing butyl rubber to produce low-hardness rubber sealing materials. When butyl reclaimed rubber and butyl rubber are used together to produce rubber sealing gaskets, it is recommended to choose butyl rubber with medium or high unsaturation degree, butyl rubber/reclaimed rubber can achieve a high degree of vulcanization in a short period of time, and improve the elasticity and low-temperature flexibility of rubber gaskets.

Butyl rubber/butyl reclaimed rubber is used to produce vulcanization formula for pipe joint sealing gaskets: 50 parts of butyl rubber, 50 parts of butyl reclaimed rubber, 4 parts of zinc oxide, 30 parts of carbon black N330, 35 parts of carbon black N990, 25 parts of paraffin oil, 0.4 parts of accelerator DM, 1.5 parts of accelerator BZ, 1.2 parts of sulfur; Total: 197.1 shares.

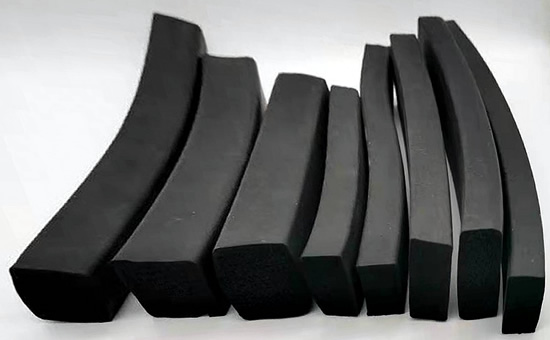

2. Butyl reclaimed rubber production buffer equipment

High-quality butyl reclaimed rubber has good elasticity, impact resistance and aging resistance, and can be used with butyl rubber and EPDM rubber to produce industrial cushioning equipment, such as cushions, shock absorbers, anti-collision blocks, buffer strips, door and window sealing strips, rubber springs, industrial casters, anti-slip mats, etc.

Butyl rubber/EPDM rubber/butyl reclaimed rubber combined production engine shock absorber vulcanization formula: 50 parts of butyl rubber, 25 parts of butyl reclaimed rubber, 25 parts of EPDM rubber, 4.2 parts of zinc oxide, 0.8 parts of stearic acid, 55 parts of carbon black N330, 25 parts of carbon black N990, 40 parts of naphthenic oil, 0.4 parts of accelerator M, 1.3 parts of accelerator TMTD, 1.3 parts of sulfur; Total: 228 copies.

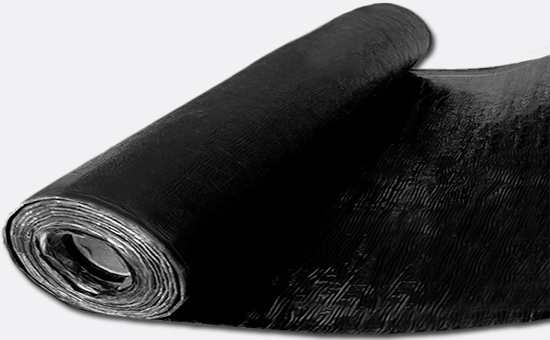

3. Butyl reclaimed rubber produces waterproof/anti-corrosion materials

Butyl reclaimed rubber has the performance characteristics of heat resistance, ozone resistance, weather resistance, strong acid resistance, etc., which can meet the performance requirements of rubber waterproof materials and anti-corrosion linings; The production of such products with butyl rubber, chlorinated butyl rubber, EPDM rubber and E4LYY38 can not only reduce the cost of raw materials, but also improve the process performance of rubber compounds and the durability of finished products. The waterproofing membranes and anticorrosive materials produced by the combination of butyl rubber and butyl reclaimed rubber are widely used in roofs, reservoirs, sewage treatment tanks, underground buildings, linings, chemical containers, etc. Adding an appropriate amount of EPDM rubber to the formula of butyl reclaimed rubber compound can further enhance the ozone resistance and weather resistance of the waterproof material.

Vulcanization formula for the combined production of butyl rubber/butyl reclaimed rubber: 65 parts of butyl rubber, 35 parts of butyl reclaimed rubber, 4.2 parts of zinc oxide, 1.8 parts of stearic acid, 1.8 parts of antioxidant, 64 parts of fine particle thermal cracking carbon black, 16 parts of easily mixed tank black, 4.5 parts of naphthenic oil, 0.4 parts of accelerator M, 1.1 parts of accelerator TMTD, 1.3 parts of sulfur; Total: 195.1 shares.

The rational use of butyl reclaimed rubber in industrial rubber products can not only reduce the cost of raw materials, but also improve the performance of rubber processing technology, especially the mixing and vulcanization process, and improve the durability of the finished product.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits