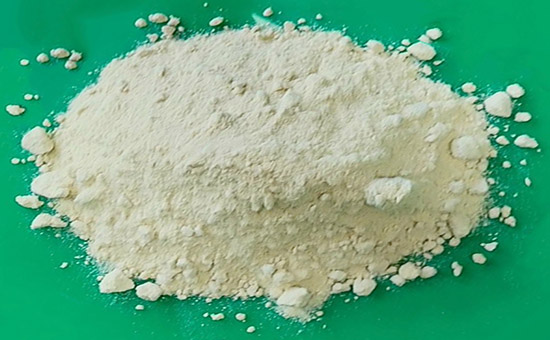

Rubber powder is made of crushed waste rubber, which is an elastomer particle with good elasticity, fluidity and adhesion, which is widely used in the plastic industry, which can not only improve the performance of plastics, but also reduce costs. In actual production, the specific use of rubber powder in different varieties of plastics is different, and today we mainly discuss with you the modification role of rubber powder in various plastics and the key points of formula design.

1. What plastics can rubber powder be used in and what is its specific function?

In the plastics industry, rubber powder can be blended with plastic in any proportion, and plastic powder can be made into toughened plastic with plastic as the substrate, and plastic powder as the substrate is plastic-to-rubber powder reinforcement. Rubber powder is blended with polyethylene, polyvinyl chloride, polypropylene, polystyrene and thermoplastic elastomers, etc., and its main role is to enhance the toughness of the material, improve the impact performance and improve the processing performance; The new rubber and plastic elastomer materials prepared after blending are made into various products by molding processing methods such as molding, lamination, calendering, injection molding, and extrusion.

2. Examples of commonly used rubber powder modified plastics

In actual production, adding fine rubber powder to polypropylene can significantly improve the toughness of plastic materials and improve impact performance. The properties of polyethylene and rubber powder blends will change with the change of blending ratio, and the properties of the blend, such as hardness and tensile strength, will increase with the increase of polyethylene content in the blend when the non-vulcanized blending process is used to E4LYY717. The use of compatibilizer to modify the rubber powder first, and then blend with polypropylene, can further improve the performance of rubber and plastic blend materials and expand the application range of rubber powder.

3. Key points of rubber powder modified plastic formula design

Polypropylene, rubber powder, crosslinker and filler can be prepared by reaction blending to produce thermoplastic elastomers with less density, lower price and easy processing than rubber; Reasonable design of rubber powder modified plastic formula can further exert the advantages of materials, which are widely used in various industrial products, especially leisure and sporting goods. In the formulation design, factors such as the particle size, surface treatment, choice of compatibilizer, and the type and amount of filler need to be considered to ensure that the performance of the final product meets the specific application needs.

There are many types of rubber powder on the market, such as tire rubber powder, nitrile rubber powder, EPDM rubber powder, etc., and the application of rubber powder with different fineness and activity in the plastic industry is different.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits