Vulcanized rubber powder is a powdery material with rubber elasticity made from waste rubber products by physical and chemical methods, including crushing, sieving, and removing non-rubber components. It can be reused as raw material in various rubber products, directly used to produce rubber products with different processes and formulations, or combined with other rubber to reduce production costs.

1. Using vulcanized rubber powder alone

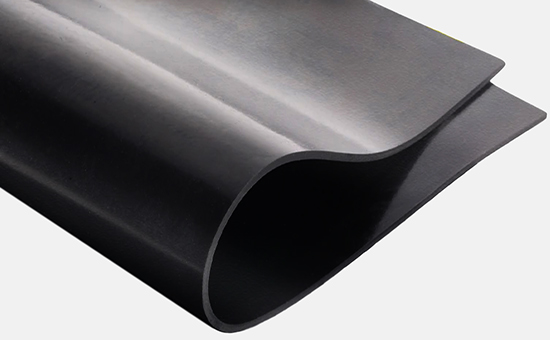

Vulcanized rubber powder itself has a cross-linked network structure and contains a small amount of unsaturated double bonds, giving it the function of re-crosslinking. It can be re-vulcanized through sulfur-accelerator vulcanization systems to produce new rubber products, such as rubber sheets, mechanical gaskets, cushioning pads, mudguards, and more.

Reference formula for producing rubber sheets entirely using rubber powder: 100 parts rubber powder, 2 parts sulfur, 1 part accelerator, an appropriate amount of softener; after evenly mixing the rubber powder with the additives, low-cost vulcanized rubber sheets can be produced under certain vulcanization temperature and pressure.

2. Vulcanized rubber powder can be used together with rubber

Vulcanized rubber powder inherits the elasticity of rubber and has good compatibility with block rubber. It can be used together with suitable types of natural rubber, synthetic rubber, and reclaimed rubber to produce rubber products, improving the processing performance of rubber compound and the wear resistance and aging resistance of rubber products, while reducing costs.

Reference formulation for producing small solid tire carcass rubber using natural rubber/styrene-butadiene rubber/vulcanized rubber powder: Styrene-butadiene rubber 60 parts, natural rubber 40 parts, vulcanized rubber powder 200 parts, zinc oxide 8 parts, stearic acid 2.8 parts, antioxidant 2 parts, carbon black 55 parts, sulfur 6 parts, accelerator 3.5 parts; total 377.3 parts.

3. Rubber powder is directly reacted and molded.

From a microscopic structural perspective, vulcanized rubber powder consists of fragments of a cross-linked network structure. Under high temperature and high pressure, the cross-linked bonds in the microstructure of the vulcanized rubber powder break down and degrade. By selecting appropriate diene reaction reagents, a Diels–Alder reaction occurs at high temperatures (200–220°C), compensating for the breakage of polysulfide cross-links, thereby achieving a balance among degradation and cross-linking, which controls the deterioration of the original vulcanized rubber properties and allows direct molding of rubber products.

4. The vulcanized rubber powder can be reactivated before reuse

Treating vulcanized rubber powder with physical, chemical, or biological methods for activation can improve its surface activity and compatibility with raw rubber; when added to rubber products, the vulcanized rubber powder has better dispersion and interfacial bonding within the rubber, thereby interacting more effectively with raw rubber and enhancing the physical and mechanical properties of the rubber products. For example, incorporating activated vulcanized rubber powder into rubber seals can improve the elasticity and sealing performance of the seals.

Vulcanized rubber powder has wide applications in the rubber products industry. Proper use of vulcanized rubber powder in rubber product manufacturing can reduce production costs, improve the processing performance of rubber compounds, and enhance the fatigue resistance of rubber products. Subsequent discussions will further explore the application techniques of vulcanized rubber powder in different types of rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits