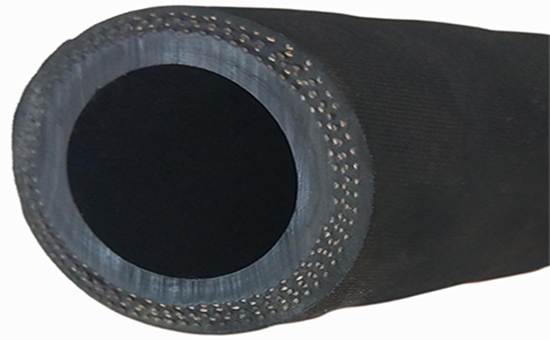

The main components of tire reclaimed rubber are natural rubber, synthetic rubber and carbon black. It has good compatibility with natural rubber and general synthetic rubber. Conveyor belts, V-belt seals, etc., effectively reduce the cost of raw materials. When using tire reclaimed rubber to produce rubber products, rational design of vulcanization formula can further optimize product quality while reducing costs.

1. Tire reclaimed rubber to produce the main material of rubber products

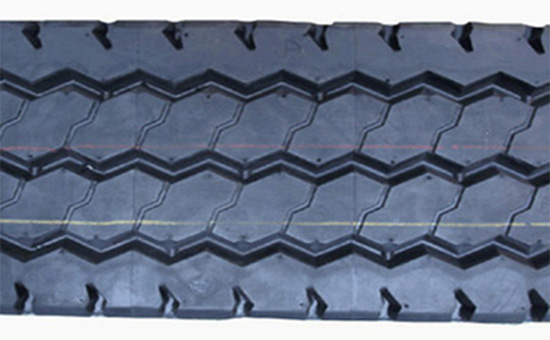

Tire reclaimed rubber can be used alone or in combination with natural rubber, styrene-butadiene rubber, butadiene rubber, isoprene rubber, etc. The use of tire reclaimed rubber alone can produce low-cost rubber sheets, rubber blocks, shock pads, rubber miscellaneous parts, etc. Using natural rubber/tire reclaimed rubber, natural rubber/styrene-butadiene rubber/tire reclaimed rubber, natural rubber/cis-butadiene rubber/tire reclaimed rubber, natural rubber/cis-butadiene rubber/styrene-butadiene rubber/tire reclaimed rubber combined rubber can produce tires, Rubber outsole, conveyor belt, V-belt, engineering rubber and other black high-strength, high-wear-resistant rubber products.

2. Commonly used vulcanization system for producing rubber products from tire reclaimed rubber

The commonly used vulcanization system for tire reclaimed rubber products is similar to that of natural rubber. In actual production, commonly used vulcanizing agents for tire reclaimed rubber include sulfur, sulfur donors, organic peroxides, esters, quinones, etc. Among them, sulfur vulcanization systems are the most common (ordinary sulfur vulcanization system, semi-effective sulfur vulcanization system and effective sulfur vulcanization system). Sulfur vulcanization system).

When using tire reclaimed rubber to replace some raw rubber to produce rubber products, take the sulfur vulcanization system as an example: compared with raw rubber, the amount of sulfur and accelerators in the production of tire reclaimed rubber products can be increased by about 20%, which will not happen like natural rubber. The specific amount can be calculated using the effective rubber content conversion algorithm; comprehensively consider the amount of tire reclaimed rubber, product quality requirements, etc.

3. Reinforcement filling system commonly used in the production of rubber products from tire reclaimed rubber

When using tire reclaimed rubber to reduce the production cost of rubber products, the reinforcing and filling system is generally reinforced with carbon black, and filled with calcium carbonate, clay, rubber powder, etc. When the tire reclaimed rubber 2ELYY913 product has high requirements on wear resistance, it is recommended to use N110, N220, N330 series reinforced carbon black; when the anti-tear performance requirements are high, grooved carbon black can be used; for elasticity and processing performance requirements When higher, N550 series quick-pressing furnace black, N660 series general furnace black, N770 series semi-reinforced furnace black, etc. can be used.

4. Anti-aging systems commonly used in the production of rubber products from tire reclaimed rubber

When using tire reclaimed rubber as the main raw material to produce rubber products, the commonly used antioxidants are antioxidant RD, antioxidant A, antioxidant DNP, antioxidant 4020, antioxidant 4010NA, antioxidant AW, antioxidant MB, antioxidant SP, antioxidant Agent SP-C, etc. Among them, tire reclaimed rubber products that have certain requirements for thermal oxygen resistance are recommended to use antioxidant RD, antioxidant A, etc.; antioxidants with good ozone resistance include antioxidant 4020, antioxidant 4010NA, antioxidant AW, etc.; non-polluting antioxidants There are antioxidant SP, antioxidant SP-C, antioxidant 246, antioxidant 2246 and so on.

5. Softening system commonly used in the production of rubber products from tire reclaimed rubber

The commonly used softeners in the production of tire reclaimed rubber products include paraffin oil, pine tar, rosin, heavy oil, asphalt, coumarone, etc. Different types of rubber products use different softeners.

To design the vulcanization formula of tire reclaimed rubber products, rubber product manufacturers need to comprehensively consider many factors such as product technical requirements, tire reclaimed rubber indicators, cost budget, and manufacturer's production equipment. Later, the editor will continue to share with you the general tire reclaimed rubber vulcanization formula.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits