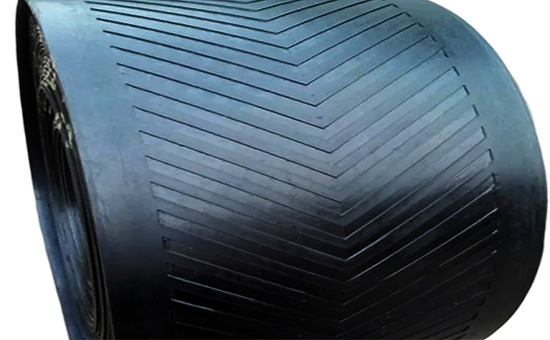

Rubber conveyor belt is a strip rubber product made of multi-layer hanging rubber canvas bonded together or with other tensile layer materials as the core, covered with rubber layer, and formed vulcanization, which can be divided into ordinary conveyor belts, special performance conveyor belts, flame retardant conveyor belts, wire rope conveyor belts, etc. according to the use. Tire recycling rubber is the product of waste tire desulfurization and regeneration, with the characteristics of wide source of raw materials and low product price, can it be used in the production of rubber conveyor belts? Which conveyor belts can use tire recycled compounds?

1. Rubber conveyor belt performance requirements

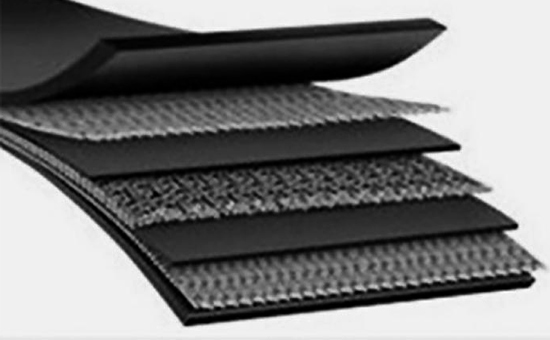

The rubber materials used in each component of ordinary rubber conveyor belts include covering rubber, buffer rubber, cloth layer adhesive, etc., while special performance conveyor belts require covering rubber to have special properties, and the performance requirements of different parts of rubber conveyor belts are different.

(1) When using ordinary rubber conveyor belt covering glue, it needs to withstand the impact, abrasion and microbial erosion of materials, as well as various aging effects, and requires the covering rubber to have good tensile strength and wear resistance, aging resistance, tear resistance, biological attack resistance and good viscosity.

(2) The conveyor belt buffer adhesive among the covering rubber and the belt core layer can increase the adhesion of the two, and can absorb and disperse the impact force of the conveyed material and play a buffering role; The rubber is required to have good adhesion, high elasticity, low heat generation, good heat dissipation and good process performance.

(3) The main function of conveyor belt cloth layer rubbing is to bond the core canvas layer into a whole. It is required to have good adhesion properties and fatigue resistance to core materials, and to have sufficient plasticity and scorching resistance and other process properties.

(4) Special performance conveyor belts mainly require covering rubber to have special properties, and other rubber formulas are the same as ordinary conveyor belts. The covering rubber of special performance conveyor belts mainly includes flame retardant, heat resistance, acid and alkali resistance, static conductivity, food conveying and other types.

2. Performance characteristics of tire recycled rubber

Tire recycled rubber is processed from waste tire rubber powder as raw material, with the basic performance characteristics of rubber, high strength, good elasticity, wear resistance, tear resistance, conveyor belt needs to withstand force and friction in the process of use, high strength and high wear resistance of tire recycled rubber (especially high strength tire tread recycled glue) can ensure that the conveyor belt is not easy to break and wear in long-term use; It can be used alone or in combination with general-purpose rubber to produce rubber conveyor belts, reducing costs.

3. What rubber conveyor belts can be produced by tire recycled rubber

The covering rubber of ordinary rubber conveyor belts is generally based on natural rubber or an appropriate amount of styrene-butadiene rubber, and the rubber content is controlled among 50%-55%; The buffer rubber is used E5LYY819 natural rubber and butadiene rubber, and the rubber content is controlled among 50%-55%; The cloth layer rubber is mainly natural rubber, and 20-30 parts of styrene-butadiene rubber can be used together, and the glue content is controlled at about 50%. Tire recycled rubber has good compatibility with natural rubber, styrene-butadiene rubber, butadiene rubber and other general rubber, which can replace some original rubber to produce different rubber layers of ordinary rubber conveyor belts, effectively reducing raw material costs and reducing labor and electricity costs.

Due to the special performance requirements of the special purpose conveyor belt covering adhesive, tire recycled rubber is generally not mixed, and the formula of other rubber layer compounds is basically the same as that of ordinary rubber conveyor belts.

Different rubber conveyor belts have different performance requirements, and the proportion of tire recycled rubber is very different. High-strength recycled rubber B is chose from 1200 waste tire tops brushed and crushed by a rubber washer and then removed impurities by magnetic separation and vibrating screen, and then produced by Belgian equipment and the most advanced high-strength segmented desulfurization process, with a fineness of more than 40 mesh, with high strength, good elasticity, small specific gravity, no migration, low Mooney viscosity, easy to operate, etc., which is an ideal raw material for the production of rubber conveyor belts by replacing natural rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits