Latex reclaimed rubber has the basic performance characteristics of natural rubber. It is an ideal raw material to replace natural rubber in daily production to produce color cloth rubber shoes Baotou rubber. When the colored latex cloth rubber shoe toe covering adhesive is prepared with light color latex reclaimed rubber as the main raw material, the reasonable design of the formula can further optimize the quality of the finished product while reducing the cost. So how to design the formula of toe covering glue for rubber shoes with recycled latex tape surface? Xiaobian takes you through the following six steps to quickly understand.

1. Selection of reclaimed rubber

When the color latex reclaimed rubber is used in the head covering rubber of cloth rubber shoes, it has high requirements on the strength and elongation of the rubber and whether it is migrated or not. It is recommended to use filter type white latex reclaimed rubber with high tensile strength, high elongation at break, less impurities and no migration; The finished product has good elasticity, high mechanical strength, uniform foaming, easy color matching and no discoloration migration. In actual production, natural rubber, non polluting styrene butadiene rubber and CIS polybutadiene rubber can also be added to the formula of latex reclaimed rubber color cloth rubber shoes Baotou rubber. The glue content of the whole formula is controlled 45% - 50%, with better comprehensive indicators and longer service life.

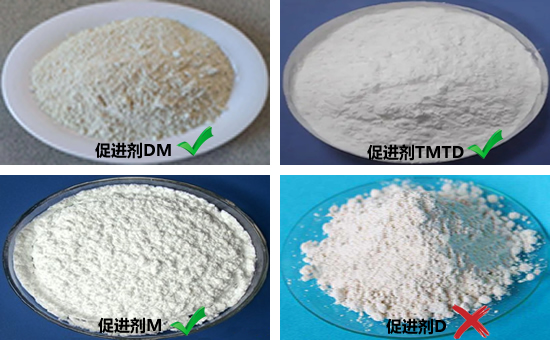

2. Vulcanization adjuvants

It is recommended to use accelerator DM, accelerator M and a small amount of accelerator D in the vulcanization adjuvants of latex recycled rubber cloth surface rubber shoes Baotou rubber, or use accelerator DM and accelerator TMTD together. When accelerator D is used as the second accelerator of thiazole accelerator, the aging resistance of vulcanizate decreases, and it will also change the color of white and light rubber products; Therefore, the dosage of D should not be too much, and the dosage of antioxidant should be increased appropriately.

3. Anti aging adjuvants

Cloth rubber shoes are generally made of anti-aging agents that are resistant to flexion, aging and discoloration. It is recommended to use antioxidant SP and antioxidant MB when using latex reclaimed rubber to produce color rubber shoes. It should be noted that accelerator M has a certain inhibitory effect on the aging resistance of antioxidant MB, while accelerator D can improve its aging resistance. Therefore, attention should be paid to the interaction of additives.

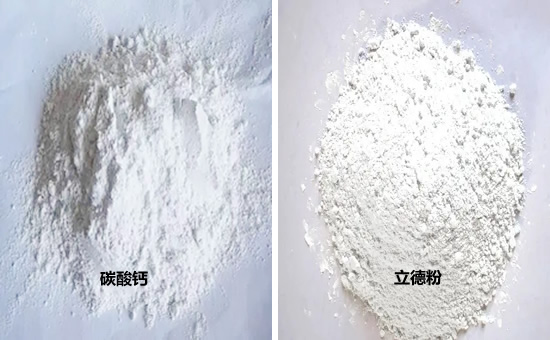

4. Filling adjuvants

In actual production, cloth rubber shoes have high requirements for the breaking elongation and bending fatigue resistance of the rubber. Calcium carbonate and lithopone in the filler can give the rubber good elongation and bending fatigue resistance.

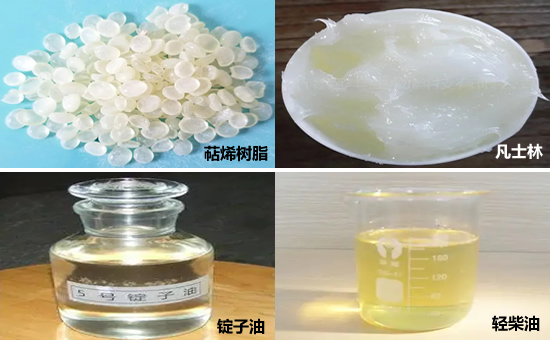

5. Softening adjuvants

When using latex colorant as the main raw material to produce light color and color cloth rubber shoes, using industrial grease and vaseline as softeners can further improve the viscosity of the rubber; If necessary, terpene resin can also be used in an appropriate amount. When calcium carbonate and other fillers are widely used for filling, an appropriate amount of Vaseline, spindle oil and light diesel oil can be added to soften.

6. Colorant

When preparing light color and color rubber shoes, non water-soluble colorants with strong coloring power, high temperature resistance, steam resistance, bright color, no discoloration, sunlight resistance and no migration should be selected, such as lithopone or titanium dioxide. In the process of practical application, 5-20 parts of lithopone or titanium dioxide can not only make the rubber colorful, but also further improve the physical and mechanical strength of the rubber.

Rational design of the formula of Baotou rubber for color cloth rubber shoes with latex reclaimed rubber as the main raw material can not only reduce the raw material cost and production energy consumption of Baotou rubber, but also further optimize the quality of finished products and prolong the service life. In the later stage, Xiaobian will continue to share with you the problems needing attention in the production process when using latex reclaimed rubber to produce cloth rubber shoes.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits