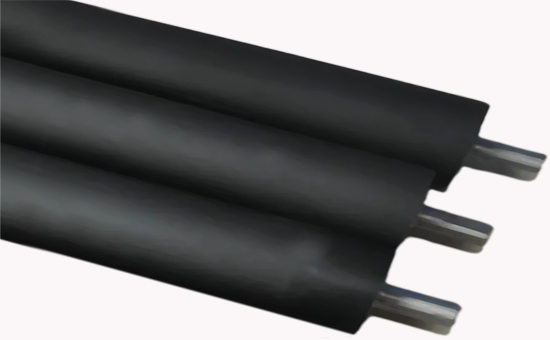

The rubber roller is made of metal or other materials as the core, and is covered with rubber for vulcanization and grinding. It has the characteristics of good elasticity, corrosion resistance and low noise. Natural rubber, with high mechanical strength and good elasticity, is a common raw material for producing rubber rollers. When using natural rubber as the main raw material to produce rubber rollers, appropriate amount of recycled latex can effectively reduce the cost of raw materials on the premise of ensuring product quality. So how to design a better formula when using natural rubber/latex reclaimed rubber to produce cots? How to adjust the mechanical strength of cots?

1. Key points for selection of reclaimed latex for rubber roller

When adding latex reclaimed rubber in the production of rubber roller with natural rubber as the main raw material to reduce the cost, it is recommended to select the latex reclaimed rubber that is close to the technical indicators of rubber roller, and use black latex reclaimed rubber for black rubber roller to reduce the cost of more raw materials.

2. Formula design of rubber roller for production of natural rubber/latex reclaimed rubber

Cots are typical thick products, and should have a long and flat vulcanization curve when vulcanizing, so as to adapt to the characteristics of low temperature and long-term vulcanization. When using natural rubber/latex reclaimed rubber 2ELYY1130 to produce rubber rollers, the sulfur accelerator system is often used, and the accelerator DM, CZ, DZ, NS are used together with sulfur, which has good vulcanization safety and high comprehensive performance of vulcanizate; In order to increase the thermal conductivity of the rubber compound, the use of zinc oxide can be increased to 50 phr at most.

3. How to adjust the hardness of natural rubber/latex reclaimed rubber roller

The hardness of top rubber is an important indicator to measure the performance of rubber cots. When the natural rubber/latex reclaimed rubber is used to produce rubber cots, the hardness of rubber cots can be adjusted by adjusting the type and amount of compounding agent in the formula.

With the increase of the amount of reinforcing agent and filler, the hardness of natural rubber/latex reclaimed rubber blends increases. The amount used in the production of rubber rollers is generally controlled below 70 phr; Too much reinforcing agent and filler will lead to difficult film bonding and easy delamination. The hardness of rubber compound can be increased by increasing the sulfur content, but the heat resistance of NR/latex recycled rubber blends will be decreased; The amount of sulfur and accelerator can be adjusted at the same time, and the crosslinking density can be adjusted to achieve the purpose of adjusting the rubber hardness. The hardness of natural rubber/latex reclaimed rubber cots can also be adjusted by increasing or decreasing the amount of softener and adjusting the type of softener. When using natural recycled rubber to produce rubber rollers with higher hardness, you can also use a proper amount of resin, such as high styrene resin.

As the replacement raw material of natural rubber, the latex reclaimed rubber can not only be used with natural rubber to produce rubber rollers, but also can produce rubber tubes, tapes, rubber strips, shoes, cable sheaths, seals, shock absorbers, etc. The white latex reclaimed rubber is used in the production of light white rubber products, which is easy to match colors and not easy to change colors. Later, Xiaobian will continue to share with you the skills of using latex reclaimed rubber to replace natural rubber to produce other rubber products to reduce costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits