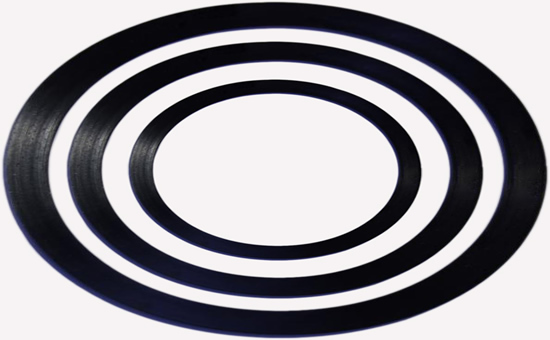

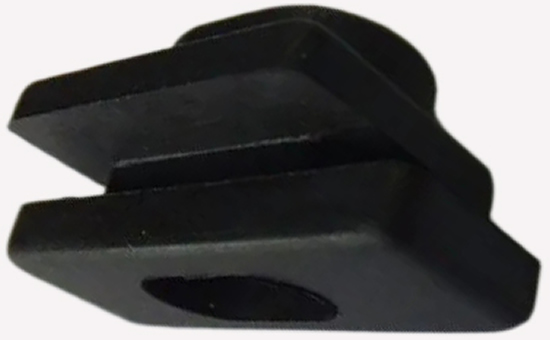

Rubber seals are mainly used for sealing machines and systems. Natural rubber is often used when rubber seals working in air, water and low concentration chemical corrosive media have no special requirements for oil resistance and heat resistance. The latex reclaimed rubber retains the basic performance characteristics of natural rubber, with high mechanical strength, elasticity, wear resistance and tear resistance. It can be used alone or together with natural rubber to produce rubber seals, effectively reducing the cost of raw materials.

When using latex reclaimed rubber to replace natural rubber with proper proportion to produce general rubber seals, rubber product manufacturers should pay attention to the following points.

1. Selection skills of latex reclaimed rubber for general rubber seals

When using reclaimed latex instead of natural rubber to produce rubber seals to reduce costs, it is recommended to select products close to the various indicators of the seals, which can replace more portions of natural rubber. Filter type latex reclaimed rubber 2ELYY1215 is used, with high fineness and no impurities, so as to better ensure the sealing effect of rubber seals; It is recommended to use environment-friendly recycled rubber for environment-friendly seals, which is pollution-free and does not migrate. Considering the price of recycled rubber, most common rubber seals are black. It is recommended to use black latex recycled rubber (the price of black latex recycled rubber with the same index is lower than that of white latex recycled rubber).

2. Selection skills of compounding agent for general rubber seals in latex reclaimed rubber production

When using reclaimed latex or natural rubber/reclaimed latex together to produce rubber products, the sulfur accelerator system or peroxide curing system can be selected as the curing system, or the DCP sulfur/accelerator composite curing system can be used. The commonly used accelerators are accelerator DM, CZ, TMTD, EZ, etc. In the reinforcement system, the different hardness requirements of rubber seals can be met by increasing or decreasing the amount of carbon black. The rubber with hot cracking carbon black and spray carbon black has small compression permanent deformation and low heat generation, which is more beneficial to the sealing effect of recycled rubber seals; High hardness rubber O-ring can combine high wear-resistant carbon black, semi reinforced carbon black and fine particle hot cracking carbon black.

3. Formula for production of rubber seals with natural rubber/latex recycled rubber

60 portions of natural rubber, 40 portions of 100% black natural latex reclaimed rubber, 5 portions of zinc oxide, 1.5 portions of stearic acid, 1 portion of antioxidant A, 1 portion of paraffin wax, 12 portions of carbon black N330, 20 portions of carbon black N774, 65 portions of light calcium, 25 portions of engine oil, 10 portions of black ointment, 10 portions of pine tar, 1 portion of accelerator DM, 0.2 portions of crude active M, and 2.5 portions of sulfur; Total: 254.2 copies. Shore hardness: about 50 degrees.

When using latex reclaimed rubber to replace a proper amount of natural rubber to produce rubber seals, rubber seal manufacturers need to fully plastic the natural rubber before mixing it with reclaimed rubber; Compared with the pure natural rubber compound, the sealant compound mixed with recycled rubber has better processability and aging resistance, and is not prone to vulcanization reversion. Later, Xiaobian will continue to discuss natural rubber/recycled rubber with you and use the reference formula to produce universal rubber seals with different hardness.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits