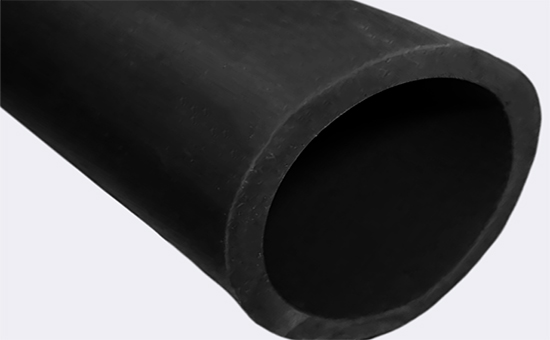

In actual production, tire tread, inner tube, tape, rubber tube, sealing strip, wire and cable sheath, waterproof coiled material, etc. are typical extruded rubber products, many of which are processed with natural rubber as the main raw material. As a substitute for high priced natural rubber, can natural latex recycled rubber be used in the production of various extruded rubber products? What problems should be paid attention to when the extruded rubber products are mixed with latex reclaimed rubber?

1. Pay attention to the indexes of reclaimed latex used for extruded products

When using latex reclaimed rubber to produce rubber products such as extruded hose, tape, rubber strip, etc., it is first necessary to select the appropriate reclaimed rubber according to the technical requirements of the extruded rubber products. Generally, high strength latex reclaimed rubber 2ELYY1227 is required for those with high mechanical strength; It is recommended to use 60-80 mesh ultra-fine latex recycled rubber, fine natural recycled rubber, etc. to ensure smooth and bright surface of products and smooth extrusion; The environment-friendly extruded rubber products use environment-friendly recycled latex, etc.

2. Pay attention to the rubber content of formula and the varieties of raw and auxiliary materials in the production of extruded products of reclaimed latex

In actual production, the higher the rubber content of the rubber compound in the formula of the reclaimed latex extrusion products, the greater the extrusion deformation. The recycled latex rubber is used together with the rubber with small extrusion deformation to improve the extrusion performance of the rubber compound. For example, the extrusion deformation of styrene butadiene rubber, neoprene rubber and butyl rubber is greater than that of cis-1,4-polybutadiene rubber and natural rubber.

Considering the varieties of rubber accessories, increasing the structure and amount of carbon black can reduce the extrusion deformation of rubber; The extrusion deformation of white filler with high activity is small. The addition of ointment and other lubricating softeners can increase the fluidity and relaxation rate of the rubber compound and reduce the extrusion deformation. In addition, the flowability of the reclaimed latex is better than that of the raw rubber, which can improve the extrusion deformation of the rubber compound.

3. Pay attention to the process conditions for the production of extruded products of latex reclaimed rubber

In actual production, the higher the plasticity is, the smaller the elasticity is, the better the rubber fluidity is, and the smaller the extrusion deformation is; On the contrary, it is larger. Therefore, appropriate measures can be taken to properly improve the plasticity of the recycled latex compound, improve the uniformity of the hot mixing of the compound before extrusion, and help to reduce the extrusion deformation. It should be noted that the plasticity of the rubber compound should not be too large, otherwise the stiffness of the semi-finished product and the physical and mechanical properties of the finished product will be affected.

Properly increasing the die temperature can increase the fluidity and relaxation rate of the reclaimed latex compound, and reduce the extrusion deformation.

On the premise of fixed extrusion temperature, with the acceleration of extrusion speed, the greater the instantaneous stress and extrusion deformation of reclaimed rubber are. The thinner the die thickness is, the shorter the time the rubber passes through the die, the less the deformation relaxation of the rubber is, and the greater the extrusion deformation is. For the compound with large extrusion deformation, adopting a slower extrusion speed and appropriately increasing the die thickness are conducive to reducing the extrusion deformation.

When using latex reclaimed rubber to reduce the production cost of extruded rubber products, rubber product manufacturers must select appropriate latex reclaimed rubber and properly adjust the production process conditions. Later, Xiaobian will continue to discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits