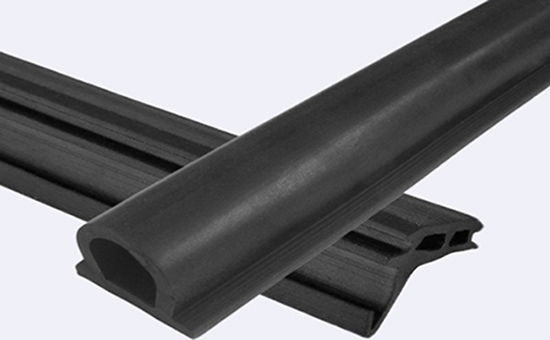

Extruded rubber products such as sealing strips, rubber tubes, etc. will be continuously vulcanized at high temperature and normal pressure. However, due to the effect of moisture in the compounding agent, these extruded rubber tubes, rubber strips and other finished products may produce air bubbles, and they need to be used properly at this time. Defoamers, namely desiccants, can effectively avoid foaming of rubber products during high temperature vulcanization. In actual production, there are many varieties of defoamer, and different defoamers are required for reclaimed rubber products in different occasions.

1. The main components of the defoamer

The main component of the rubber defoamer is calcium oxide with fine particle size. During the mixing and vulcanization process, calcium oxide will combine with the trace moisture in the compounding agent to produce calcium hydroxide and avoid foaming during high temperature vulcanization. The use of reclaimed rubber 2ELYY314 to produce extruded rubber hoses, extruded rubber strips, etc., and appropriate use of fine-grained calcium oxide can eliminate the influence of moisture on the performance of vulcanized rubber; In other words, this method is very common and can effectively avoid the generation of air bubbles.

2. Physical and chemical properties of defoamer for reclaimed rubber

The ideal rubber defoamer should have the following characteristics: it has a lower surface tension than the foam medium; it is insoluble in the foam medium; it does not react with the foam medium, and cannot be decomposed by the foam medium; Diffusion to the gas-liquid interface; non-toxic or low toxicity; storage stability; good defoaming ability and foam control ability; low cost. When choosing a defoamer for extruded reclaimed rubber products, performance and cost must be considered comprehensively, and costs must be reduced on the premise of ensuring the smooth extrusion of hoses and tapes.

3. Commonly used defoamer for reclaimed rubber products

(1) Calcium oxide: When using reclaimed rubber to produce rubber sealing strips and rubber pipes, calcium oxide or surface-coated calcium oxide is commonly used. Good dispersion, no effect on vulcanization speed, basically will not affect the physical and mechanical properties and thermal aging properties of reclaimed rubber products. This defoamer is generally stored in a closed container, avoiding contact with water and water vapor, and away from heat sources.

(2) New rubber brightener: mainly used to solve the problem that the surface of black molded or extruded rubber products is not black and shiny, absorbs the moisture of rubber and accessories (more than 32% of its own weight) after use, and improves the fluidity of the rubber. , to form a black and bright protective film on the rubber surface; it plays the role of eliminating microporous bubbles, promoting vulcanization, and improving the toughness of rubber products, usually the addition ratio in the original rubber is 5% and 10%; using reclaimed rubber to produce extruded hoses , rubber strip and other extrusion products, it can be added together with the accelerator, the dosage is 5%-8%, and there is no conflict with the original formula.

(3) Other defoamers: silicone-based defoamers, with low surface tension, low volatility, chemical inertness, and good stability. Organic defoamer can be either a single compound or a mixture according to a certain formula, such as aluminum soap of stearic acid or oleic acid, copolymer of propylene glycol and ethylene glycol, polyethylene glycol, etc.

When using reclaimed rubber to produce extruded rubber products, in order to ensure the smooth extrusion of the products and no bubbles, a defoamer is essential. The editor will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits