The main function of shock-absorbing rubber products is to eliminate and reduce the transmission of mechanical vibration, and ultimately achieve the purpose of silence, vibration reduction and impact reduction. Common rubber air springs, rubber shock-absorbing pads, rubber pads, etc. Rubber powder processed from waste rubber products can be used in the production of shock-absorbing rubber products, effectively reducing the cost of raw materials while ensuring the product quality.

1. Rubber spring with scrap tire powder

Rubber air spring is a curved capsule made of rubber as the main raw material. It uses air as the medium to balance, buffer and transfer pressure. In the actual application process, different parts of the rubber air spring have different performance requirements. In general, the outer rubber layer of air spring needs to be aging resistant, flexibility resistant, good adhesion to the curtain, and has a higher constant elongation stress. The inner layer needs to be ageing resistant, low breathability and good adhesion to the curtain. The curtain layer requires the rubber to have high flexibility, heat resistance and adhesion.

In actual production, 10-20 parts of fine tire regenerated rubber powder can be used in the rubber air spring inside, outside and curtain rubber layers. Sulfur sulfur sulfurization is recommended, the outer rubber is filled with super-abrasive black and semi-reinforcement carbon black, and the inner rubber and curtain rubber are filled with semi-reinforcement carbon black to further optimize the mechanical parameters of the product. The rubber spring produced with the above formula can effectively reduce the cost of raw materials and sulfur energy consumption.

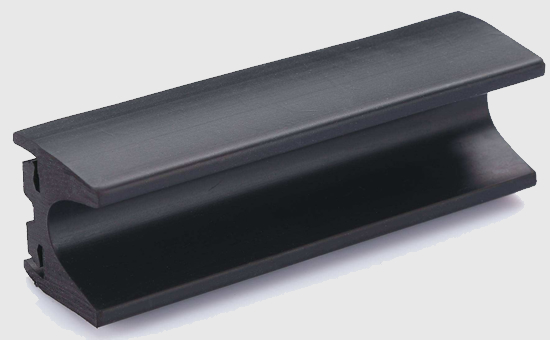

2. Rubber fender with activated tire powder

Rubber fender is a collision-proof equipment used by wharf ships. Its main function is to reduce the impact of ships and wharfs or ships during docking or mooring, and to eliminate or reduce the damage to ships and wharfs. In practice, rubber fenders are generally processed with styrene-butadiene rubber as the main raw material. Large amounts of activated rubber powder can effectively reduce production costs while guaranteeing the physical and mechanical properties of the rubber. In actual production, with the increase of the amount of activated tire rubber powder, the amount of operating oil, zinc oxide, sulfur and accelerator in the formula of rubber fender can be increased appropriately, and the amount of mixing agent can also be adjusted appropriately according to the specific requirements of rubber fender.

Rubber powder can be divided into coarse rubber powder, fine rubber powder, fine rubber powder, etc. according to the fineness, according to the source of raw materials, it can be divided into tire rubber powder, latex powder, nitrile rubber powder, ethylene propylene rubber powder, etc. According to the surface activity, it can be divided into vulcanized rubber powder and activated rubber powder, and the usability of different rubber powder is different. In actual production, the application of rubber powder in shock-absorbing rubber products is not only limited to air springs, rubber fenders, but also can be used for brake pads, conveyor belts, waterproof rolls, friction materials, etc. Later editions have the opportunity to continue discussing with you the application of latex recycled rubber powder, nitrile recycled rubber powder, acetylene propylene recycled rubber powder in rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits