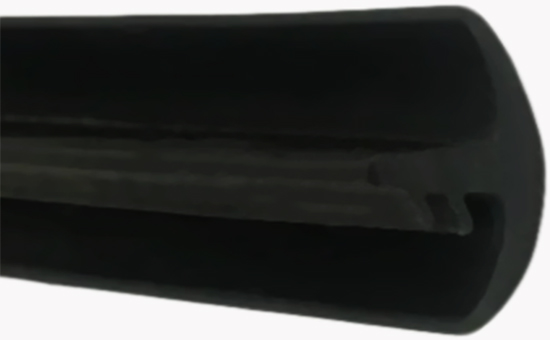

Rubber sealing strip has good sealing effect, which can effectively prevent external air, dust, water, etc. from entering the system, and is widely used in automobiles, aircraft, engineering vehicles, building doors and windows, refrigerators, etc. In actual production, rubber sealing strip requires good processing safety, low Mooney viscosity, no frost spraying, small discoloration, low compression permanent deformation, etc; When there is no special requirement for ozone resistance and aging resistance, natural rubber or natural rubber/synthetic rubber can be used for production; The production cost of rubber sealing strip can be effectively reduced by replacing part of natural rubber with latex reclaimed rubber.

1. Addition method of latex regeneration adhesive in rubber sealing strip

In actual production, manufacturers can use natural rubber alone to produce rubber sealing strips, or use natural rubber and neoprene together, or use natural rubber, neoprene and styrene-butadiene rubber together to produce rubber sealing strips, or use natural rubber and polypropylene together, or natural rubber and EPDM together to produce rubber sealing strips. The natural latex reclaimed rubber 2SLYY214 has the basic performance characteristics of natural rubber, and can directly replace part of natural rubber and natural rubber to produce rubber sealing strips, or can be used with natural rubber, neoprene, styrene-butadiene rubber, ethylene-propylene rubber, polypropylene, etc., to effectively reduce production costs on the premise of ensuring the quality of the finished sealing strips.

2. Tips for selecting latex reclaimed rubber for rubber sealing strip

When using latex reclaimed rubber to replace part of natural rubber to produce rubber sealing strips, it is necessary to select appropriate natural reclaimed rubber according to the application situation, color and various mechanical index requirements of sealing strips. In actual production, it is recommended to select the latex reclaimed adhesive with physical and mechanical properties close to the sealing strip; In terms of color, black latex reclaimed rubber can be used for black and dark rubber sealing strips (the price of black natural reclaimed rubber is lower), and white latex reclaimed rubber or color latex reclaimed rubber of corresponding color can be used for white and color sealing strips (easy to match color and not easy to change color); The latex reclaimed rubber without impurities and pungent smell shall be used, and the environment-friendly latex reclaimed rubber shall be used for the production of indoor rubber sealing strips.

The replacement ratio of latex reclaimed rubber to replace natural rubber to produce rubber sealing strips needs to be determined according to the rubber content of natural reclaimed rubber, for example, 85% black latex reclaimed rubber can replace natural rubber according to 1.3: 1; Properly adjust the curing system, reinforcement system and softening system of the original formula of the sealing strip.

3. Reference formula for production of rubber sealing strip with natural rubber/latex recycled rubber

70 parts of natural rubber, 30 parts of latex regenerated rubber, 5 parts of zinc oxide, 1.2 parts of stearic acid, 1 part of antioxidant A, 0.5 parts of paraffin, 15 parts of carbon black, 175 parts of light calcium, 10 parts of oil, 20 parts of white ointment, 0.3 parts of accelerator D, 0.7 parts of accelerator DM, 0.4 parts of accelerator M, and 2.5 parts of sulfur; Total: 331.6 copies.

When using natural reclaimed rubber to replace some natural rubber to produce rubber sealing strips, the rubber product manufacturer must select the appropriate latex reclaimed rubber products, reasonably design the formula of rubber products, and properly adjust the production process parameters. The following editor will continue to discuss with you the issues that need attention in the production process of mixing rubber sealing strips with latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits