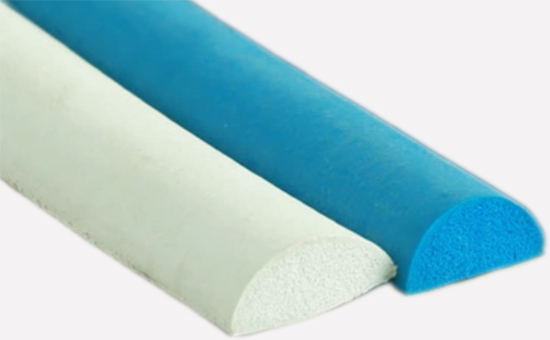

Sponge rubber sealing strip has the characteristics of light texture, good elasticity and flexibility, wear resistance, tear resistance, etc., and has good sealing, buffering, shock absorption and temperature insulation effects during use, and is widely used in construction, automobiles, machinery and equipment and other fields. In actual production, the light-colored ordinary sponge rubber sealing strip is mostly processed with natural rubber as the main raw material, and the appropriate use of latex reclaimed rubber can not only reduce the cost of raw materials, but also improve the process performance of rubber and the aging resistance of the finished product.

1. Mixed with latex reclaimed rubber to produce light-colored sponge rubber sealing strip vulcanization formula

70 parts of natural rubber, 30 parts of butadiene rubber, 30 parts of latex reclaimed rubber, 6 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant MB, 1 part of antioxidant SP, 80 parts of light calcium carbonate, 50 parts of talc, 1 part of paraffin, 12 parts of engine oil, 1.65 parts of accelerator DM, 0.35 parts of accelerator TMTD, 3.1 parts of sulfur, 3.6 parts of foaming agent H; Total: 292.2 shares.

The above formula is also suitable for the production of sponge sealing products such as large sponge rubber sealing rings.

2. Latex reclaimed rubber production of light-colored sponge rubber sealing strip raw material selection skills

When using latex reclaimed rubber to reduce the cost of natural rubber/styrene-butadiene rubber light-colored sponge rubber sealing strips, it is recommended to choose reclaimed rubber that is close to the index of sealing strips, which can replace more parts of natural rubber and reduce the cost of raw rubber. Latex reclaimed rubber can be divided into black latex reclaimed rubber, white latex reclaimed rubber E4LYY327 and red, green, yellow, blue latex reclaimed rubber, etc. When producing light-colored sponge sealing strips, it is recommended to choose white latex reclaimed rubber, or colored latex reclaimed rubber that is close to the color of the finished product, which is easy to match; Choose environmentally friendly latex reclaimed rubber, especially indoor products, which are non-polluting, non-radiation, and non-permeable.

3. Mixing latex reclaimed rubber to produce light-colored sponge rubber sealing strip compounding agent selection skills

Latex reclaimed rubber has the characteristics of high mechanical strength, good elasticity, wear resistance and tear resistance, and good compatibility with natural rubber, which can directly replace the appropriate proportion of natural rubber to produce light-colored sponge rubber sealing strips.

When natural rubber/latex reclaimed rubber is used together to produce light-colored sponge rubber sealing strips, choose more sulfur-accelerator system, and appropriately increase the amount of sulfur and accelerator. When using foaming agent H, pay attention to the vulcanization rate of the sponge sealing strip should match the foaming speed. Appropriately increasing the amount of reinforcing agent and reducing the amount of filler can further optimize the quality of the finished sponge rubber sealing strip containing latex reclaimed rubber and prolong the service life.

Sponge rubber sealing strip is a commonly used sealing material, which combines the elasticity of rubber and the softness of sponge, and has a wide range of applications in pipeline valve sealing, door and window sealing, automobile sealing, mechanical equipment sealing, building sealing and other occasions; Choosing the right latex reclaimed rubber and designing the formula reasonably can effectively reduce the production cost and improve the sealing effect and aging resistance of the light-colored natural rubber sponge foam sealing strip.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits