Natural rubber is expensive and its price fluctuates significantly. Manufacturers of natural rubber products use a certain amount of natural rubber substitutes in their formulations to reduce costs. Secondary grade natural rubber and reclaimed natural latex rubber both have the basic performance characteristics of natural rubber and are much cheaper than natural rubber, making them the main raw materials for substituting natural rubber. What are the differences among these two rubber raw materials? Which material is more suitable for producing products as a substitute for natural rubber?

1. Secondary grade natural rubber

Secondary grade natural rubber is a by-product of the natural rubber production process, where certain indicators do not meet the standards of primary grade rubber. Essentially, it is still natural rubber, with a high content of effective rubber hydrocarbons, retaining the good elasticity, relatively high strength, excellent wear resistance, and good flexibility and tear resistance of natural rubber. It can directly replace a suitable proportion of primary natural rubber in the production of natural rubber products, reducing raw material costs.

2. Reclaimed natural latex rubber

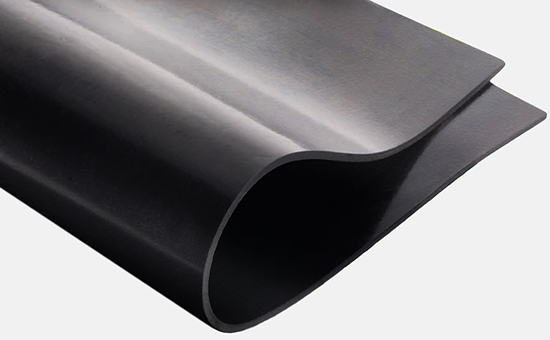

Reclaimed natural latex is made from waste natural rubber, waste latex, and their products as raw materials. Through processes such as crushing, desulfurization, disinfection, drying, and filtering, it retains the basic properties of natural rubber. It features high strength, low density, good hand feel and elasticity, easy coloring, fine texture, eco-friendliness with no odor, high elongation at break, and a simple open-mill process. It can be used alone or together with natural rubber to produce products, effectively reducing raw material costs and saving electricity and processing costs.

3. Techniques for choosing low-cost option raw materials for natural rubber

Which is better, secondary natural rubber or natural latex reclaimed rubber? Both secondary natural rubber and latex reclaimed rubber have their own advantages and disadvantages, so it is not easy to simply judge which is better. The choice depends on the specific application scenarios and requirements.

When natural rubber products have strict requirements for rubber content and mechanical strength, it is recommended to use secondary-grade natural rubber or latex reclaimed rubber with high rubber content. For example, products like tires and conveyor belts, which need to withstand significant pressure, friction, and impact during use, can benefit from secondary-grade natural rubber that provides sufficient strength and durability. Common rubber miscellaneous items, rubber flooring, adhesive tapes, rubber mats, and rubber soles can use latex reclaimed rubber, which is more cost-effective. For extruded natural rubber products or products that require finer quality, filtered latex reclaimed rubber is recommended, such as thin-walled rubber hoses and rubber balls.

In actual production, secondary-grade natural rubber can also be used together with reclaimed natural latex rubber to achieve the optimal balance among cost and performance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits