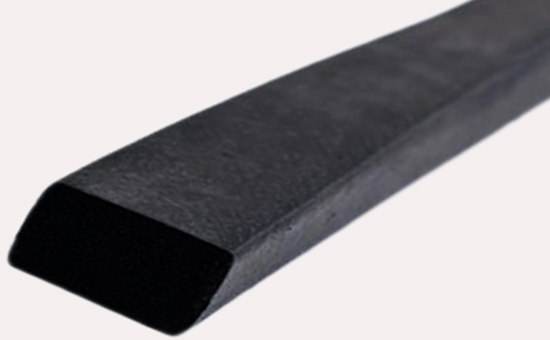

EPDM reclaimed rubber has good high and low temperature resistance and aging resistance. It can be used alone or in combination with EPDM raw rubber to produce rubber products such as door and window seals, effectively reducing the cost of raw materials. When EPDM reclaimed rubber, EPDM/reclaimed rubber and rubber are used to produce rubber products with relative movement, the high friction coefficient of the rubber itself will increase the wear of materials and resistance to relative movement, which will lead to premature damage or sticking of materials. Therefore, when using EPDM recycled rubber to produce rubber products such as transmission belt, sealing strip and sealing element, it is necessary to improve the abrasion resistance of rubber.

There are many factors that affect the abrasion resistance of EPDM recycled rubber products. Small friction coefficient, high tensile strength, large elongation, tear resistance, fatigue resistance, good elasticity, etc. are beneficial to improve the abrasion resistance of vulcanizate. Xiao Bian today shares with you several methods to improve the abrasion resistance of ethylene propylene diene monomer recycled rubber from the perspective of cooperation.

1. Reduce friction coefficient and improve abrasion resistance of ethylene propylene diene monomer recycled rubber

In actual production, any method to reduce the friction coefficient of ethylene propylene diene monomer recycled rubber is beneficial to improve the wear resistance, mainly including the following points:

① The hardness of the rubber compound is increased, the rubber resistance to deformation is enhanced, and the depth of the protrusion part of the friction surface pressed into the rubber becomes shallow, which can reduce the friction coefficient. ② The friction coefficient can be reduced by increasing the ethylene content of raw rubber or mixing some thermoplastic plastics such as PE and PP. ③ The use of additives that are easy to form interface lubricating film, such as some lubricating additives, can effectively reduce the friction coefficient, but these materials are easy to migrate, which may cause pollution or frost on the material surface.

④ Adding a small amount of graphite, molybdenum disulfide and silicone resin can reduce the friction coefficient, especially the dry friction coefficient; Adding hard ceramic filler (such as silicon nitride) can also reduce the friction coefficient, but it is generally only used in reciprocating seals. ⑤ The friction coefficient can be reduced by increasing the elasticity and vulcanization degree of the vulcanizate and reducing the viscosity and hysteresis of the rubber compound. ⑥ Phenolic resin, coumarone resin, tackifier, etc. can improve the surface activity of materials and increase the friction coefficient. They should be avoided in low friction compounds.

2. Reasonably use carbon black to improve the abrasion resistance of ethylene propylene diene monomer recycled rubber

The ethylene propylene diene monomer recycled rubber and ethylene propylene diene monomer raw rubber can obtain higher strength after being reinforced. High strength is beneficial to improving the abrasion resistance of rubber compound. Therefore, the combination of reinforcement filling system is an important factor affecting the abrasion resistance of ethylene propylene diene monomer recycled rubber 2ELYY1031. Generally, the abrasion resistance is improved with the increase of the amount of reinforcement filler. After the peak value, the abrasion resistance of ethylene propylene diene monomer recycled rubber compound decreases with the increase of the amount.

① In actual production, carbon black with high abrasion resistance or medium to super abrasion resistance, such as N330, N220, etc., is selected. EPDM recycled rubber vulcanizate has the best abrasion resistance. The abrasion resistance of rubber compound can be improved by improving the dispersion uniformity of carbon black and the factors of interaction among carbon black and macromers. The interaction among grooved carbon black and macromolecules is improved due to the special surface chemical properties. The EPDM reclaimed rubber vulcanizate using grooved carbon black has high abrasion resistance.

② It is recommended to use white carbon black instead of carbon black for reinforcing light colored rubber products such as car door and window sealing strips produced with ethylene propylene diene monomer recycled rubber. Due to the formation of filler network, ethylene propylene diene monomer (EPDM) filled with white carbon black can improve the tear resistance and cut resistance of rubber compound, and the abrasion resistance of vulcanizate is good. The wear resistance of EPDM reclaimed rubber vulcanizate can be further improved by using proper amount of coupling agent to improve the dispersion uniformity of silica and its interaction with macromolecules.

Considering the influence of hardness on wear resistance, generally with the increase of hardness, the friction coefficient decreases and the wear resistance improves. However, after the hardness reaches a certain value (generally around 80), the elasticity or cushioning effect of the rubber becomes worse. If the hardness continues to increase, the wear resistance of the rubber may decrease.

In actual production, the abrasion resistance of EPDM recycled rubber compound with common sulfur curing system is better than that of other systems; The use of softener can improve the processing properties of the rubber compound, and the excessive mixing of softener reduces the rubber content of the rubber compound, which will reduce the abrasion resistance of ethylene propylene diene monomer recycled rubber; In the future, we will continue to share with you the key points for the formulation of various EPDM recycled rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits