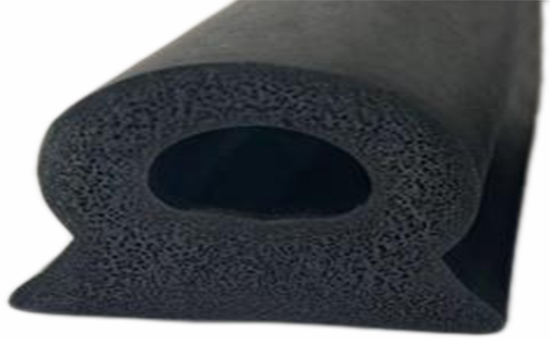

Rubber sealing strip is a sealing product made of rubber as the main material, which uses the elasticity of the lip, cavity, flange and other parts to produce contact pressure with the surface of the contact object to achieve the sealing effect, and is widely used in automobiles, aircraft, railways, engineering vehicles, building doors and windows and various household appliances. EPDM rubber has excellent resistance to high and low temperatures, weather resistance, ozone resistance and aging resistance, and is an ideal raw material for the production of sealing strips. With the intensification of market competition, many companies have begun to use reclaimed rubber in EPDM sealing strips.

1. What reclaimed rubber can be mixed in EPDM rubber sealing strips?

Although EPDM rubber can meet the performance requirements of most rubber sealing strips, its market price is high, and it will harden after aging. The price of reclaimed rubber is lower than that of EPDM, with good plasticity, good fluidity, low processing power consumption and aging resistance. Reclaimed rubber in EPDM sealing strip can not only reduce the cost of raw materials, reduce labor and electricity costs, but also improve the aging resistance of products (EPDM rubber and a small amount of butyl reclaimed rubber can be used together to improve the problem of aging and hardening of rubber compounds).

EPDM rubber can be completely used in the production of EPDM rubber sealing strips, and EPDM rubber can be used together with EPDM reclaimed rubber and butyl reclaimed rubber to produce sealing strips to reduce costs. When using reclaimed rubber to reduce the production cost of EPDM rubber sealing strips, reasonable design of the formula and selection of appropriate compounding agents can further improve the comprehensive performance of the product.

2. EPDM rubber sealing strip containing reclaimed rubber is commonly used as a fitting system

To design the formula of EPDM rubber sealing strip containing reclaimed rubber, sulfur-accelerator system or peroxide cross-linking is generally selected, and carbon black, silicate or calcium carbonate can be used for the reinforcing filling system; It should be noted that the EPDM rubber sealing strip with peroxide 2SLYY116 vulcanization should be used with caution to avoid affecting the peroxide vulcanization. EPDM recycled rubber sealing strip plasticizer mostly uses paraffin hydrocarbon oil or paraffin oil, which must be low polarity and less volatile; Non-reactive phenolic resins such as alkyl phenolic resins can be used as tackifiers.

When EPDM rubber/EPDM reclaimed rubber is used together to produce rubber sealing strips with excellent aging resistance, the protective system can use antioxidants and antioxidants together, such as antioxidant 4010NA and antioxidant RD and antioxidant AW; In the light-colored rubber compound, phenol antioxidant and physical antioxidant can be used together. When EPDM rubber is used in combination with EPDM reclaimed rubber or butyl reclaimed rubber to produce sponge sealing strips, it is necessary to consider the balance among the hole velocity and vulcanization speed generated by the foaming agent and the vulcanizing agent after use according to the process performance requirements.

EPDM rubber/reclaimed rubber can also be added with an appropriate amount of supportive compounding agents, such as ointment, polymer wax, modified plastics, etc., and the finished rubber compound has good stiffness and small deformation.

3. How to improve the extrusion process performance of EPDM/reclaimed rubber sealing strips

The design of EPDM rubber sealing strip formula containing reclaimed rubber also needs to fully consider the extrusion process performance of the rubber compound. The use of ointment, mineral oil, clay, stearic acid and other compounding agents can improve the extrusion speed of semi-finished products and keep them smooth; The use of ointment and magnesium carbonate can reduce the deformation of semi-finished products in the parking time; Appropriately improving the plasticity of the rubber compound and increasing the fluidity of the rubber compound can make the surface of the semi-finished product smoother, reduce the scorch during extrusion and increase the extrusion speed.

In the production of EPDM rubber sealing strips, the varieties and addition ratios of reclaimed rubber need to be determined according to the performance requirements of the sealing strips.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits