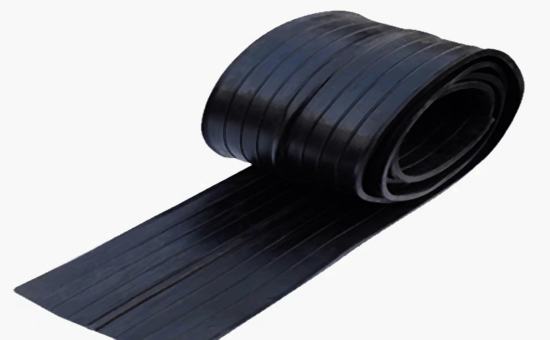

Rubber waterstop is an important rubber waterproof sealing material made of natural rubber or synthetic rubber as the main raw material, through plasticizing, mixing, pressing and molding processes, with good elasticity, wear resistance, aging resistance, tear resistance and other performance characteristics, is widely used in construction engineering, traffic engineering, water conservancy engineering and other fields. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, which can not only ensure the performance of waterstop when used in waterstop production, but also effectively reduce the cost of raw materials.

1. EPDM reclaimed rubber produces rubber waterstop vulcanization formula

100 parts of EPDM reclaimed rubber, 2 parts of zinc oxide, 1.24 parts of stearic acid, 0.6 parts of paraffin, 10 parts of carbon black N550, 10 parts of calcium powder, 1.7 parts of petroleum resin, 0.56 parts of accelerator DM, 0.52 parts of accelerator CZ, 0.09 parts of accelerator TMTD, 1.12 parts of sulfur; Total 127.83 copies.

Vulcanization temperature 180°C; The vulcanization time is determined according to the thickness of the product and is 35 seconds per millimeter.

2. Key points of the formula design of EPDM reclaimed rubber production rubber rubber for rubber waterstops

(1) Selection of reclaimed rubber

When using EPDM reclaimed rubber as the main raw material to produce rubber waterstops, it is recommended to choose EPDM reclaimed rubber with higher rubber content, such as Hongyun EPDM reclaimed rubber, compared with ordinary sealing strip EPDM reclaimed rubber, higher glue content, better elasticity, greater mechanical strength, high and low temperature resistance, anti-aging, weather resistance, and anti-erosion performance, which is used in the production of rubber waterstops, which can better ensure the performance of the waterstop.

EPDM reclaimed rubber can also be used with an appropriate amount of ultra-fine tire reclaimed rubber to produce rubber waterstops, further reducing production costs.

(2) EPDM reclaimed rubber waterstop compounding agent selection

EPDM reclaimed rubber is commonly used in the production of rubber waterstops, and it is recommended to use accelerator DM, accelerator CZ, accelerator TMTD or accelerator M with sulfur, and the vulcanized rubber has good physical properties and good processing performance E4LYY88. Carbon black is the most commonly used reinforcing agent, including high wear-resistant carbon black, semi-reinforcing carbon black, fast-pressed carbon black, etc., according to the requirements of physical properties to select the appropriate variety and dosage; Fill the appropriate amount of calcium carbonate to reduce the cost of raw materials. The softener can use petroleum resin, paraffin oil, naphthenic oil, etc., to improve processability.

In actual production, EPDM reclaimed rubber waterstop can also use peroxide vulcanization, generally using TAIC, HAV-2, PL400 and other cross-linking additives with DCP, vulcanized rubber heat aging resistance, compression deformation resistance is good, but the cost is high, the process performance is poor; If necessary, a small amount of sulfur can be added to improve the processing technology performance and physical and mechanical properties of the rubber material.

Rubber waterstop is mainly used to prevent leakage at structural joints, and is a commonly used waterproof material in construction engineering, water conservancy engineering, tunnel engineering and other fields, with good elasticity, flexibility and waterproof performance. When using EPDM reclaimed rubber as the main raw material to produce rubber waterstops, waterstop manufacturers must choose the appropriate EPDM reclaimed rubber, reasonably design rubber formulas, strictly control production process parameters, ensure the quality of finished products, and reduce the cost of more raw materials.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits