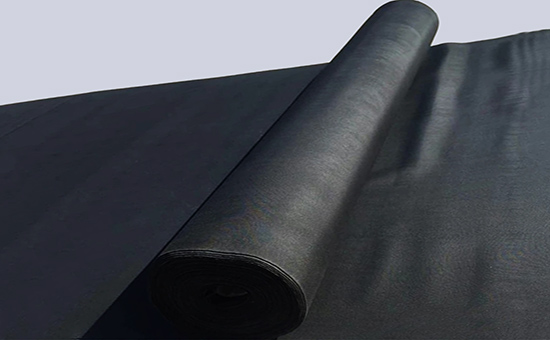

EPDM rubber has excellent weathering and aging resistance, making it an ideal raw material for manufacturing roofing waterproof membranes. However, EPDM rubber is relatively expensive, so can lower-cost rubber materials be used as substitutes? EPDM recycled rubber is processed from EPDM scrap, uncured EPDM rubber, and waste EPDM rubber products, retaining the basic performance characteristics of original EPDM rubber, such as high and low-temperature resistance, ozone resistance, and weather resistance. It can be used in the production of roofing waterproof membranes to reduce costs.

1. Application methods of EPDM recycled rubber in roofing waterproof membranes

When using EPDM recycled rubber to reduce costs in roofing waterproof membranes, there are three main application methods:

① Using EPDM recycled rubber alone to produce waterproof membranes, optionally adding 0-10 parts of short fibers or waste tire rubber powder as reinforcing materials; ② EPDM recycled rubber has good compatibility with EPDM rubber and can be used in appropriate proportions to produce roofing waterproof membranes, which can increase extrusion speed and reduce shrinkage; ③ EPDM recycled rubber can also be blended with butyl rubber or recycled butyl rubber to produce waterproof membranes, improving the aging and hardening of EPDM compounds and extending the service life of roofing waterproof membranes.

2. Selection of compounding agents for producing roofing waterproof membranes with EPDM recycled rubber

When producing roofing waterproof membranes with EPDM recycled rubber, it is recommended to use a sulfur-accelerator system. Common accelerators include TMTD, ZDC, and BZ as main accelerators, with thiazole accelerators M and DM as auxiliary accelerators, providing vulcanizates with high physical and mechanical properties and good vulcanization uniformity. Reinforcement systems can combine high wear-resistant carbon black with semi-reinforcing carbon black, selecting fillers such as light calcium carbonate, kaolin, and talc E5LYY630. The ratio of carbon black to kaolin needs to balance the mechanical performance and economic efficiency of recycled rubber vulcanizates. For softening agents, it is recommended to choose low-volatility, high-aniline-point paraffinic oils or naphthenic oils to prevent post-production shrinkage of roofing waterproof membranes, or add a small amount of Gurmaron resin to improve adhesion to cement or adhesives.

3. Reference formula for producing roofing waterproof membranes using EPDM recycled rubber, butyl rubber, and recycled butyl rubber

EPDM recycled rubber 45 parts, butyl rubber 20 parts, recycled butyl rubber 35 parts, zinc oxide 3.5 parts, stearic acid 1.3 parts, antioxidant 1.5 parts, high wear-resistant carbon black 35 parts, kaolin 50 parts, talc 20 parts, paraffinic oil 20 parts, accelerator NC 0.65 parts, accelerator TMTD 1 part, accelerator M 1 part, accelerator PZ 0.65 parts, sulfur 2 parts; total 236.6 parts.

When producing roofing rubber waterproof membranes using EPDM recycled rubber, it is necessary to select recycled EPDM rubber with appropriate specifications according to the specific requirements of the membrane, reasonably determine the amount and method of recycled rubber incorporation, and adjust the rubber formula appropriately to reduce raw material costs while ensuring the performance of the roofing waterproof membranes.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits