Short fiber has the characteristics of high set elongation, cutting resistance, tear resistance, puncture resistance, low heat generation, low compression deformation and so on. quantity. When using short fiber reinforced reclaimed rubber, the reclaimed rubber is the continuous phase and the short fiber is the dispersed phase, and an interface layer will be formed among the two phases. strong effect. Therefore, when reclaimed rubber is reinforced with short fibers, three practical issues need to be paid attention to: dispersion, bonding and orientation.

1. Dispersion of short fibers in reclaimed rubber

In actual production, in order to ensure that the short fibers can be quickly dispersed in the reclaimed rubber and the fibers are subject to minimal damage, the rubber product manufacturer must carry out some preparations. The following measures are recommended to improve the dispersion of short fibers in reclaimed rubber:

(1) Latex-short fiber co-precipitation pretreatment method.

(2) Mucilage-short fiber co-precipitation method: The water dispersion of short fibers is slowly mixed into the rubber solution under stirring, the rubber solution of short fibers is obtained by separation, and the organic solvent is evaporated with steam at 100 °C to obtain a pre-dispersion. .

(3) Mechanical dispersion method: special mechanical dispersion of fiber bundles is used, and then added to the rubber solution under stirring, and vacuum-dried to obtain pretreated short fibers.

(4) Dry glue blending method: A small amount of rubber, a certain amount of lubricant and a large amount of short fibers are uniformly made into a short fiber pre-dispersion.

(5) Coating with powder filler: Use carbon black or white carbon black in the formula to mix short fibers to keep the fibers in a separated state.

2. Adhesion of the interface layer among short fibers and reclaimed rubber

Dip pretreatment of short fiber 2ELYY419, or add tackifier in rubber formulation, can improve the bond strength among short fiber and reclaimed rubber. In actual production, the bonding of the interface layer has an important influence on the properties of the reclaimed rubber-fiber reinforced material. The pretreated short fibers are used in the production of reclaimed rubber products, and the tensile strength and tear strength of the finished products are higher.

3. Orientation of short fibers in reclaimed rubber

The orientation of short fibers has three directions, the axial direction (L) consistent with the calendering direction, the direction (Y) that is in the same plane as L and perpendicular to the calendering direction (T) and the vertical L-T plane. After the reclaimed rubber is mixed, the short fibers need to be oriented by the viscous flow of the rubber and the shear tensile strength effect of the roller of the rubber mixer, and the short fibers need to be oriented by calendering, extrusion and other processes. After short fiber orientation, the tensile strength parallel to the fiber direction greatly exceeds the tensile strength perpendicular to the fiber orientation.

The reclaimed rubber mixing process affects the orientation. If the orientation direction can be paid attention to during the mixing process, it is very beneficial for the preparation of highly oriented materials. In actual production, the degree of orientation determines the degree of anisotropy in the properties of reclaimed rubber composites. The most intuitive method to detect the degree of orientation is observation by optical microscope and electron microscope, or supplemented by image analyzer detection. For the reclaimed rubber material reinforced with short fibers, the tensile strength and flexural modulus are larger in the L direction than in the T direction, and the wear resistance in the Y direction is the best.

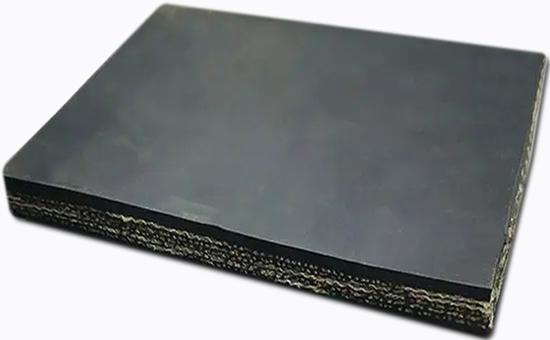

When using reclaimed rubber to produce rubber pipes, V-belts, conveyor belts, tires, seals, waterproof sheets, shock absorbers and other products, it is possible to use short fibers, such as 5-20 parts of short fibers in the compression layer of the V-belt It can obviously improve the lateral rigidity of the V-belt, has better longitudinal flexibility, lower flexural modulus, significantly improves the side friction of the V-belt, improves the transmission efficiency, and is not easy to slip during use. An in-depth understanding of the dispersion, bonding and orientation of short fibers in reclaimed rubber is of great significance to improving the comprehensive index of reclaimed rubber products and expanding the scope of application of reclaimed rubber. The editor will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits