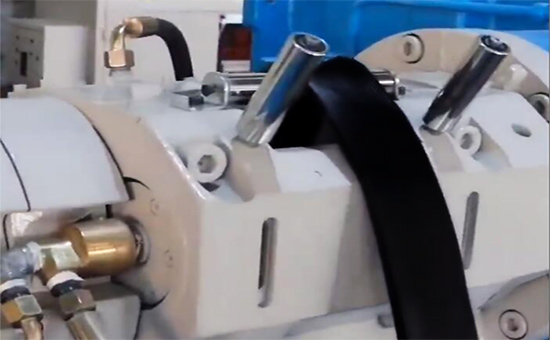

When using reclaimed rubber to produce rubber products, extrusion is one of the basic processes. After the recycled rubber enters the extruder, the length of the semi-finished product decreases (shrinks) and the cross section increases (expands) due to the elastic effect of the rubber after it flows through the mouth shape. Therefore, when designing the formula of the recycled rubber extruded rubber, it is necessary to fully consider the extrusion expansion rate; The design of reinforcement filling system directly affects the extrusion expansion rate of recycled rubber; To improve the extruding performance of reclaimed rubber, it is necessary to reasonably design the reinforcing filling system of the vulcanization formula of reclaimed rubber.

After the filler is added to the reclaimed rubber extruded compound, the rubber content of the compound decreases, and the elastic deformation of the compound is reduced, thus reducing the extrusion expansion rate. Carbon black is the most commonly used reinforcing filler in the production of recycled rubber products. Generally, with the increase of carbon black dosage, the extrusion expansion rate of recycled rubber compound decreases. The structure degree, particle size and activity of carbon black will affect the extrusion expansion rate of recycled rubber.

In general, the carbon black aggregates with high structure have high porosity, forming more absorbing and retaining rubber, thus reducing the volume fraction of free rubber in the system; Therefore, the carbon black used in the extruded compound of reclaimed rubber 2ELYY119 has high structural degree and small expansion rate. Compared with the structure degree, the influence of carbon black particle size on the extrusion expansion rate of recycled rubber was relatively small; In the case of the same structure, the carbon black with small particle size and high activity has a greater impact on the extruding performance of reclaimed rubber than the carbon black with low activity.

The structure degree and amount of carbon black have an equivalent relationship with the extrusion expansion rate of recycled rubber compound: the reduction of expansion rate of low structure and large amount is equivalent to that of high structure and small amount. In actual production, properly increasing the amount and structure of carbon black can significantly reduce the extrusion expansion rate of recycled rubber compound. Too much high structure carbon black or activated carbon black will cause difficulty in pressing, and the particle size of carbon black is more important for low structure carbon black at this time.

During the preparation of the reclaimed rubber extruded compound, the amount of filler in the extruded compound shall not be less than a certain amount. For example, it is recommended to control the amount of carbon black in the reclaimed butyl rubber or butyl rubber/reclaimed rubber compound to be more than 40 parts by weight, or the amount of inorganic filler to be more than 60 parts by weight.

When the reclaimed rubber is used as the main raw material to prepare the extruded compound, the molecular structure of rubber/reclaimed rubber (molecular chain flexibility and intermolecular force, relative molecular weight, relative molecular weight distribution, degree of branching), rubber content and softening growth rate system will also affect the extrusion performance of the compound. Later, we will continue to discuss relevant issues.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits