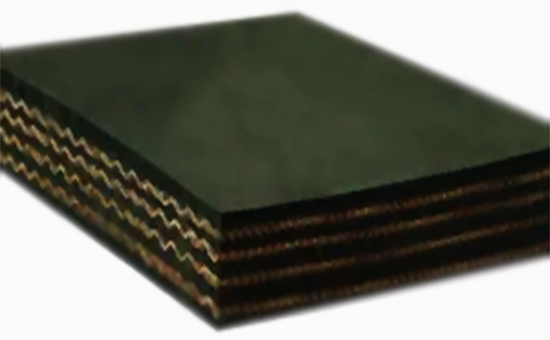

When the recycled rubber is used as the main raw material to produce rubber products such as rubber tubes, rubber V-belts, and automobile tires, the elastic modulus of the rubber can be significantly improved by using a proper amount of short fiber reinforcement. The short fiber itself has a large length diameter ratio, which is difficult to mix and disperse in the recycled rubber, and generates large heat during mixing. Therefore, when using short fiber for reinforcement of recycled rubber products, the fiber needs to be treated in advance, and the mixing process conditions need to be adjusted properly during mixing.

1. Surface treatment of short fiber

In actual production, short fibers include natural fibers, synthetic fibers and chemical fibers, and their wettability with rubber and recycled rubber is poor

It is recommended to conduct surface treatment on the short fiber in advance to further improve the wettability and adhesion among the short fiber and the rubber, so as to ensure that the short fiber can be better mixed and finely dispersed in the rubber.

2. Key points of mixing process of recycled rubber reinforced with short fiber

In actual production, short fiber mixing consumes a lot of energy. When using internal mixer or open mixer to mix recycled rubber products reinforced with short fiber, attention should be paid to the temperature and hardness of rubber materials; The rubber discharging temperature and mixing quality can be controlled by using proper filling coefficient, top bolt pressure and roll pitch.

(1) Key points for mixing recycled rubber reinforced with short fiber in internal mixer

When the recycled rubber is mixed in the internal mixer, it is recommended to use low rotating speed to promote the dispersion of short fiber rubber, and at the same time, the temperature of rubber is not too high, which is better than mixing in the open mixer. When the recycled rubber 2ELYY1226 is mixed with the mixing agent, in order to prevent excessive heat generation of the rubber containing short fibers, the loading coefficient should be appropriately reduced. Generally, the loading coefficient of the rubber containing short fibers is 81% - 93% of that of the non fiber rubber; For example, the filling coefficient of EPDM rubber without fiber material is about 0.65, and that of rubber with short fiber is about 0.59.

In actual production, the short fiber is easy to roll off on the tablet press, which can appropriately increase the glue discharge temperature to the maximum allowable value, and reduce the roll spacing to 5-8mm; Change the operating position (easy wrapping roll) or change the speed ratio of the roller of the tablet press.

(2) Notes on mixing of recycled rubber reinforced with short fiber in open mill

When the rubber reinforced with short fiber is mixed in the open mill, the fiber is easy to be oriented in the rotation direction of the roller, which will cause the rubber to roll off; To avoid roll off, it is necessary to properly improve the open mill conditions. In general, it is recommended to control the front roll temperature at 25-30 ℃ and the rear roll temperature at about 70 ℃ for open mill mixing without speed ratio. The recycled rubber compound reinforced with short fiber is mixed in an open mill with speed ratio, and the rear roll is fast, the temperature of the front roll is 25-35 ℃, and the temperature of the rear roll is 70-90 ℃; The front roll is fast, the temperature of the front roll is controlled below 30 ℃, and the temperature of the rear roll is controlled among 30-50 ℃.

3. Key points of vulcanization process of recycled rubber reinforced with short fiber

High temperature is harmful to textiles in rubber products. When the temperature of cotton fiber cloth exceeds 140 ℃, its strength will drop, and it will be completely destroyed when heated at 240 ℃ for 4h.

When short fibers are needed to reinforce rubber products such as rubber hoses, tapes, tires, seals, etc. for the production of recycled rubber, the rubber product manufacturer must treat the short fibers in advance according to the actual needs, and adjust the mixing process parameters appropriately; Later, the editor will continue to share relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits