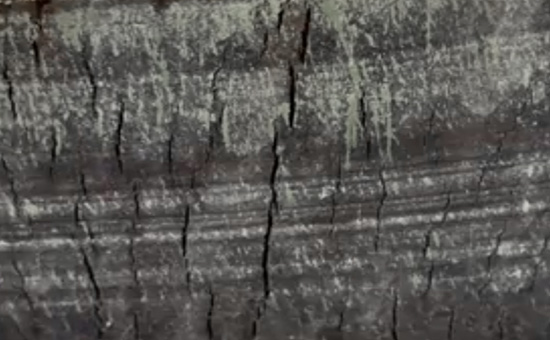

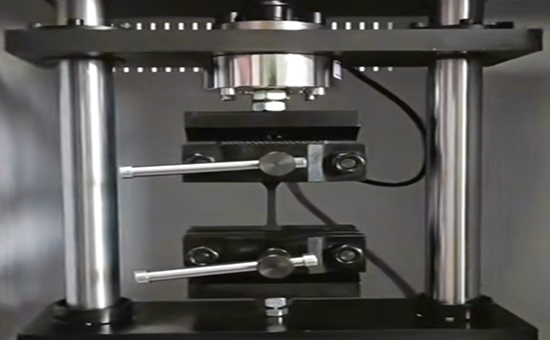

"Fatigue" occurs when the structure and properties of rubber change under dynamic tension, compression, shear or bending, and the purpose of rubber fatigue resistance is to maintain the physical and mechanical properties of its original design for a long time. When using reclaimed rubber to produce rubber products, improving the fatigue resistance of rubber can significantly extend the service life of rubber products, and manufacturers of reclaimed rubber products can improve the fatigue resistance of reclaimed rubber by adjusting the variety and dosage of compounding agents in the rubber vulcanization system, filling system, softening system and anti-aging system.

1. How to design a vulcanization system to improve the fatigue resistance of reclaimed rubber

The vulcanization system is a key factor affecting the fatigue resistance of reclaimed rubber. Selecting the appropriate vulcanizing agent and accelerator in the formulation of reclaimed rubber products can significantly improve the fatigue resistance of vulcanized rubber. In general, the reclaimed rubber vulcanized with peroxide vulcanization system has better fatigue resistance than the rubber vulcanized with sulfur vulcanization system. Appropriately increase the amount of cross-linking agent, increase the cross-linking density, and improve the fatigue aging resistance of reclaimed rubber.

2. How to design a reinforcing filling system to improve the fatigue resistance of reclaimed rubber

The reinforcing filling system has an important impact on the fatigue resistance of reclaimed rubber. As a commonly used reinforcing agent, the structure and specific surface area of carbon black have a significant impact on the fatigue resistance of rubber. Carbon black with higher structure can produce more dense rubber phase around carbon black particles, thereby improving the fatigue damage resistance of vulcanized rubber. Soft carbon black with moderate particles has good fatigue resistance. In the white filler, the reclaimed rubber is filled with silica, which can improve the fatigue aging resistance of the rubber compound.

For fillers that have no affinity with rubber, the larger the particle size of the inert filler, the larger the filling amount, and the worse the fatigue resistance of the reclaimed rubber vulcanized rubber. When designing the reinforcing filling system of reclaimed rubber products, the type, dosage and particle size of the filler, as well as their compatibility with reclaimed rubber, should be considered to improve the fatigue resistance of reclaimed rubber.

3. How to design a softening plasticization system to improve the fatigue resistance of reclaimed rubber

Softening plasticizers can reduce the hardness and viscosity of reclaimed rubber and improve processability, but it can also affect fatigue resistance. Choosing a softening plasticizer with a high softening point can improve the fatigue life; Reactive softening E4LYY65 plasticizers enhance the relaxation properties of rubber molecules, making stretch crystallization easier and thus improving fatigue damaging. When designing the softening plasticizer system of reclaimed rubber, the amount of softener should be minimized, and the compatibility and reactivity of softening plasticizer and reclaimed rubber should be considered to improve fatigue and damage resistance.

4. How to design an anti-aging system to improve the fatigue resistance of reclaimed rubber

Antioxidants play an important role in improving the fatigue resistance of reclaimed rubber. Antioxidants can prevent oxidative degradation of reclaimed rubber during fatigue, thereby prolonging fatigue life. Choosing the right antioxidants, such as aryl alkyl and dialkyl-p-phenylenediamine antioxidants, can improve the protective effect. The protective effect of antioxidant is also related to the vulcanization system, and the protection effect of reclaimed rubber sulfur vulcanized rubber is the best. When designing the anti-aging system, the type, dosage and compatibility with the reclaimed rubber should be considered, as well as the application environment of the final product, so as to improve the fatigue resistance of the reclaimed rubber.

In the production of reclaimed rubber products, the reasonable design of vulcanization system, reinforcing filling system, softening plasticization system and anti-aging system can effectively improve the fatigue resistance of reclaimed rubber, reduce costs, and expand the application range of reclaimed rubber in high-performance rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits