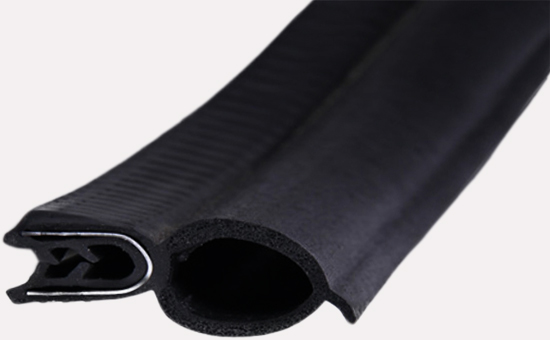

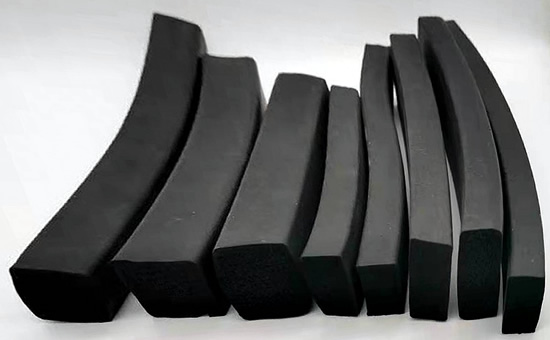

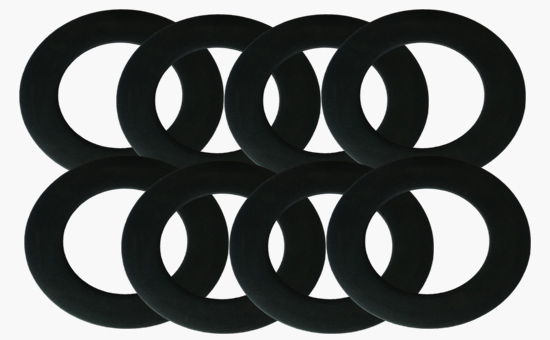

Rubber sealing products are mainly used in various mechanical devices, which play a good sealing role, prevent the leakage of fluid medium in a static or moving state, and prevent external dust, sediment and other impurities from entering the sealing mechanism. As a new raw material to replace high-priced raw rubber, reclaimed rubber can effectively reduce the cost of raw materials in the production of rubber sealing products. The use of reclaimed rubber to produce all kinds of rubber sealing products, vulcanization is one of the important production processes, so what is the purpose of vulcanization of reclaimed rubber sealing products? How do I design the vulcanization parameters?

1. The purpose of vulcanization of recycled rubber sealing products

Vulcanization is the process of adding vulcanizing agents and accelerators and other cross-linking additives to rubber to transform linear macromolecules into three-dimensional network structure under certain temperature and pressure conditions, so that the semi-finished rubber compound with plasticity becomes a vulcanized product with elasticity and low deformation, which significantly improves the tensile strength, wear resistance and elasticity of rubber, and enhances the aging resistance and chemical corrosion resistance of rubber; The product has a certain shape and specified dimensional accuracy, and the reclaimed rubber seal is not easy to deform when used.

2. Vulcanization temperature setting for recycled rubber sealing products

In the process of rubber vulcanization, the vulcanization temperature can soften the rubber and promote the flow of the rubber material. Improve the activation energy of sulfuration chemical reaction and promote sulfur cross-linking; The rubber and compounding agents (such as activators, accelerators, vulcanizing agents) are activated to produce cross-linking and form a three-dimensional network structure. When using reclaimed rubber E4LYY813 to produce rubber sealing products, the vulcanization temperature is different depending on the type and formula. Generally, when natural latex reclaimed rubber is used to produce sealing products, the vulcanization temperature is about 150 °C; When nitrile rubber is vulcanized with peroxide, the vulcanization temperature can reach 180 °C, and the vulcanization temperature of other vulcanization systems is below 170 °C.

When vulcanizing recycled rubber sealing products, the vulcanization temperature is too high, which will cause the rubber molecular chain to break or decompose; The temperature is too low, the vulcanization speed is slow, and the production efficiency is low. The scorching time of the rubber material is short, and the curing time is fast, which affects the fluidity and adhesion of the rubber material, and is prone to quality problems such as lack of glue, scorch marks, poor joints, out-of-tolerance size, and excessive thickness of waste edges.

3. Vulcanization pressure setting for recycled rubber sealing products

The vulcanization pressure can close the mold, so that the rubber flow fills the model, and the material is dense, so that all parts of the recycled rubber composite seal are tightly bonded and form a whole; Make the seal pattern clear and the size meets the requirements; Proper vulcanization pressure can extrude the gas in the rubber compound and make the surface of the rubber seal product smooth.

The thick products, high hardness products and special-shaped structure products produced by reclaimed rubber require large pressure, usually the cavity pressure of molded products is among 7-25MPa, and excessive pressure not only causes waste but also easily damages equipment and molds; If the pressure is too small, it will affect the dimensional accuracy and material compactness of the recycled rubber sealing products, and then affect the physical properties of the sealing products.

4. Vulcanization time setting for recycled rubber sealing products

Rubber vulcanization needs to be carried out within a certain period of time, and vulcanization time is an important parameter to ensure that the vulcanization reaction is carried out and the recycled rubber sealing products reach a positive vulcanization state, especially for thick products. The vulcanization time of reclaimed rubber sealing products depends on the rubber formulation, product properties, thickness, vulcanization system of the rubber compound, glue consumption and vulcanization temperature. Typically, for every 10°C increase in temperature, the vulcanization time is halved.

In the vulcanization process of reclaimed rubber sealing products, the vulcanization time is too long, which will produce supersulfur, and the physical properties of the rubber will decrease, especially the thermal tearing performance will deteriorate; If the vulcanization time is too short, it is easy to have quality problems such as lack of sulfur and sticking mold.

Rubber sealing products are a large category of rubber products, such as sealing rings, sealing strips, sealing gaskets, oil seals, leather bowls, etc. When using reclaimed rubber to produce sealing products, reasonable setting of vulcanization parameters can further improve the performance of finished products while reducing the cost of raw materials for sealing products and meet more needs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits