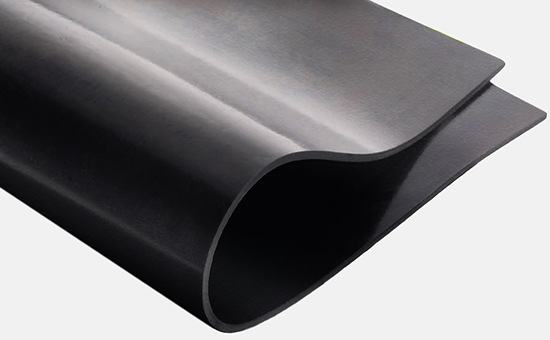

Industrial rubber plate is a sheet rubber product with a certain thickness and a large area prepared by vulcanization with rubber as the main material; However, the price of natural rubber and synthetic rubber is high, and the cost of using raw rubber to produce ordinary industrial rubber sheets is high. The thermoplastic elastomer prepared by blending polyvinyl chloride, reclaimed rubber and vulcanized rubber powder in an appropriate proportion can be directly molded by an extruder to process ordinary rubber sheets, reduce the cost of raw materials and simplify the production process.

1. The basic characteristics of reclaimed rubber, PVC and vulcanized rubber powder

(1) Reclaimed rubber: waste rubber products through physical and chemical processes such as crushing, heating, mechanical and chemical treatment, so that they can be processed and vulcanized from an elastic state to a certain plasticity and viscosity, which can be processed and vulcanized, and retains the basic performance characteristics of rubber, such as elasticity, tensile strength, elongation at break, etc., the price is much lower than that of original rubber, plasticity and fluidity, which can replace natural rubber and synthetic rubber to produce ordinary industrial rubber plates, effectively reducing production costs.

(2) Polyvinyl chloride: a linear polymer polymer polymerized by vinyl chloride monomer through general free matrix polymerization reaction, with good chemical resistance, dielectric, flame retardancy and high mechanical strength, and can be blended with rubber to prepare thermoplastic elastomers, with good processing properties, mechanical properties and aging resistance.

(3) Vulcanized rubber powder: a powdery substance with different particle sizes made of waste rubber as raw material through mechanical processing and crushing or grinding, with a wide range of particle sizes, good elasticity and wear resistance. Vulcanized rubber powder can be blended with polyvinyl chloride to prepare thermoplastic elastomers, which can improve the processing performance of PVC, enhance toughening and reduce costs.

2. Points to note for the preparation of thermoplastic elastomers by blending reclaimed rubber/PVC/vulcanized rubber powder

(1) Rational use of compatibilizers

PVC is a polar material, and reclaimed rubber and vulcanized rubber powder are non-polar materials, so the compatibility of PVC with reclaimed rubber and vulcanized rubber powder is poor, and it is necessary to add compatibilizers to improve the interface bonding. The commonly used compatibilizers for the blending of reclaimed rubber/PVC/vulcanized rubber powder are nitrile rubber NBR-18 and ENR-50, which have good compatibilization effect and the dosage is controlled among 4-6 parts.

(2) Add an appropriate amount of plasticizer

When blending reclaimed rubber/PVC/vulcanized rubber powder, dioctyl phthalate (DOP) and heavy aromatic oil are selected as plasticizers, which can reduce the glass transition temperature of PVC and improve the flexibility and processing fluidity of the blend.

3. Reclaimed rubber/PVC/vulcanized rubber powder thermoplastic elastomer to produce ordinary industrial rubber sheets

Reclaimed rubber, polyvinyl chloride and vulcanized rubber powder to prepare thermoplastic elastomers, dynamic vulcanization at 160-170 °C can prepare extrudates with good appearance, high tensile strength E4LYY1223 and elongation at break, good processing performance and good tear resistance; The ordinary industrial rubber plate is prepared by extruder molding, which has low raw material cost, low production energy consumption, and stable comprehensive performance of the finished industrial rubber sheet.

Reasonable control of the blending ratio of PVC, reclaimed rubber and vulcanized rubber powder, as well as the amount of compatibilizer and plasticizer, can produce low-cost industrial rubber board with excellent comprehensive performance; Compared with ordinary industrial rubber sheets produced by natural rubber, the manufacturing cost can be reduced by more than 30%.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits