Rubber waterproof coiled materials are sheet rubber products with large area processed from rubber as the main material, mainly used for building walls, roofs, underground and other occasions, to prevent rain and snow water from seeping into the room or groundwater from seeping into the building. In actual production, neoprene rubber, styrene butadiene rubber, ethylene propylene diene monomer rubber, butyl rubber or several kinds of rubber can be used alone for rubber waterproof roll. As a renewable resource of waste rubber, the price of tire recycled rubber is low. Can it be added to the production of waterproof coiled materials? What problems should we pay attention to?

1. Application mode of tire recycled rubber in waterproof roll

In actual production, the recycled tire rubber can be used alone or together with styrene butadiene rubber, chloroprene rubber, etc. to produce vulcanized waterproof coiled materials, effectively reducing production costs. Compared with vulcanized waterproofing membrane, non vulcanized waterproofing membrane has lower manufacturing cost; The cost of raw materials can be further reduced by using recycled tire rubber instead of blending synthetic rubber and asphalt to prepare non vulcanized waterproof coiled materials.

2. Selection skills of recycled tire rubber for waterproof roll

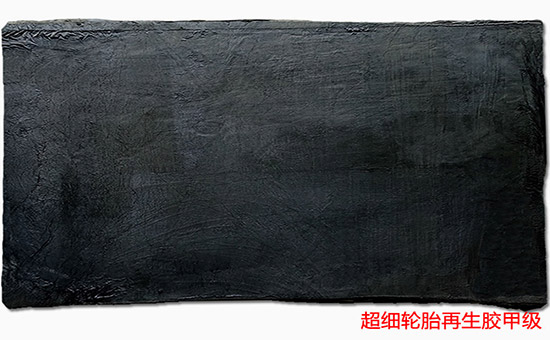

When using tire recycled rubber to reduce the cost of vulcanized rubber waterproof coiled material, it is recommended to use superfine tire top recycled rubber and fine tire recycled rubber 2ELYY1124 for waterproof coiled material with high physical property requirements. The comprehensive performance of waterproof coiled material is better; Low grade waterproof roll can directly use ordinary tire recycled rubber, with lower price. In the preparation of non vulcanized waterproof coiled materials, the recycled tire rubber can also be used together with the recycled sole rubber, and mixed with asphalt to prepare waterproof materials with lower cost.

3. Reference formula of waterproof coiled material prepared from recycled rubber

(1) The formula for the production of vulcanized waterproof coiled materials from recycled rubber: 150 shares of recycled rubber, 25 shares of oil extended styrene butadiene rubber, 1 share of antioxidant D, 1 share of paraffin wax, 1 share of stearic acid, 35 shares of carbon black N330, 4 shares of engine oil, 0.2 shares of accelerator D, 0.8 shares of accelerator DM, and 220.5 shares of sulfur.

Vulcanization condition: 148 ℃ × 40min。 Reference physical indexes of finished waterproof roll: tensile strength 8.3MPa, elongation at break 30%.

(2) Formula for production of non vulcanized waterproof coiled materials from recycled rubber: 30 portions of recycled rubber from tires, 20 portions of No. 10 petroleum asphalt, and 50 portions of light calcium carbonate; Total: 100 copies.

Reference physical properties of finished waterproof roll: tensile strength (transverse) ≥ 0.78MPa, elongation at break (longitudinal).

In actual production, recycled tire rubber is an ideal rubber raw material for preparing low-cost waterproof rolls. Later, Xiaobian will continue to share with you the techniques of reducing costs by mixing other recycled rubber into rubber waterproof rolls and the key points of the production process of recycled rubber waterproof rolls.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits