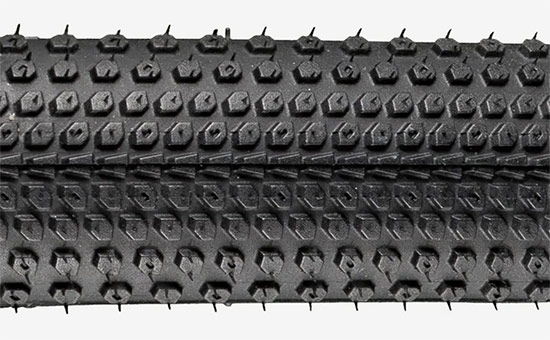

The outer tire sidewall compound of bicycle tires can be divided into black sidewall compound and colored sidewall compound, mainly used to prevent mechanical damage, atmospheric effects, and moisture effects on the tire body. In actual production, the black sidewall rubber of bicycle tires is generally processed from natural rubber, natural rubber/butadiene rubber, natural rubber/chloroprene rubber, and natural rubber/butadiene rubber/chloroprene rubber as raw materials; Adding a small amount of recycled tire rubber can not only reduce raw material costs, but also improve the processing performance of the black tire side and reduce production energy consumption.

1. Vulcanization formula for producing black sidewall rubber for bicycle outer tires using natural rubber/recycled tire rubber

100 parts natural rubber, 10 parts recycled tire rubber, 5 parts zinc oxide, 3 parts stearic acid, 1 part paraffin, 1 part antioxidant D, 2 parts antioxidant 4010, 25 parts carbon black N774, 20 parts mixed carbon black, 1.3 parts light calcium, 2.5 parts pine tar, 1.2 parts accelerator M, 0.5 parts accelerator DM, and 2.5 parts sulfur; Total: 175 copies.

2. Vulcanization formula for producing black sidewall rubber for bicycle outer tires using natural rubber/polybutadiene rubber/recycled tire rubber

50 parts of natural rubber, 50 parts of butadiene rubber, 10 parts of recycled tire rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 2 parts of antioxidant D, 1.5 parts of paraffin, 35 parts of carbon black N330, 2 parts of pine tar, 4 parts of petroleum jelly, 0.6 parts of accelerator DM, 0.7 parts of rough calculation CZ, and 1.7 parts of sulfur; Total: 166 copies.

3. Vulcanization formula for producing black sidewall rubber for bicycle outer tires using natural rubber, polybutadiene rubber, and chloroprene rubber

50 parts natural rubber, 20 parts cis-1,4-polybutadiene rubber, 30 parts chloroprene rubber, 5 parts zinc oxide, 2.3 parts stearic acid, 1.5 parts antioxidant A, 1.5 parts antioxidant D, 1.5 parts paraffin, 22 parts carbon black N330, 20 parts carbon black N774, 6 parts liquid coumarone resin, 2 parts petroleum jelly, 2 parts zinc oxide, 0.3 parts promoter DM, 0.6 parts promoter CZ, and 1.3 parts sulfur; Total: 166 copies.

Compared with natural rubber, cis-1,4-polybutadiene rubber, chloroprene rubber and other raw materials, tire recycled rubber has better plasticity and flowability, is easy to mix with raw rubber and compounding agents, and is less prone to vulcanization and reversion; Reasonable use of recycled tire rubber 2SLYY46 can not only reduce raw material costs, but also improve the processing performance of the rubber material, improve the flexibility, aging resistance, and puncture resistance of the black sidewall rubber for bicycle outer tires; In the future, the editor will continue to share with you the techniques and vulcanization formulas for reducing the cost of raw materials for other parts of bicycle tires using recycled tire rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits