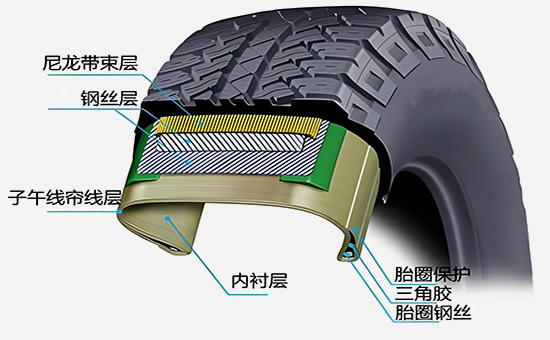

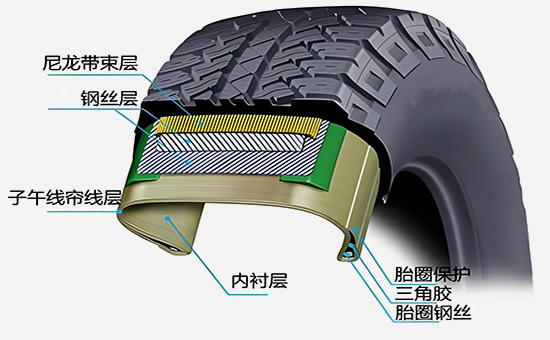

The carcass cord of radial tires is arranged in the direction of the radial line, at a 90-degree angle to the central axis of the tire, which can provide higher load carrying capacity, lower rolling resistance, better wear resistance and better handling. Radial tire carcass nylon cord rubber refers to the rubber layer applied to the radial tire carcass part, attached to the nylon cord, generally processed with natural rubber, styrene-butadiene rubber, isoprene rubber, etc. as the main raw materials, and the appropriate amount of tire reclaimed rubber can effectively reduce the cost of raw materials.

1. Styrene-butadiene rubber/tire reclaimed rubber and vulcanized formula for the production of radial tire carcass, nylon cord layer rubber

60 parts of styrene-butadiene rubber, 40 parts of tire reclaimed rubber, 3 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant RD, 28 parts of carbon black N550, 7 parts of aromatic oil, 0.15 parts of accelerator D, 0.8 parts of accelerator DM, 1.85 parts of sulfur; Total: 142.8 shares.

2. Natural rubber/styrene-butadiene rubber/tire reclaimed rubber and vulcanization formula for the production of radial tire carcass, nylon cord layer rubber

50 parts of natural rubber, 35 parts of oil-filled styrene-butadiene rubber, 15 parts of tire reclaimed rubber, 3 parts of zinc oxide, 1.6 parts of stearic acid, 1 part of antioxidant RD, 30 parts of silica, 3 parts of aromatic oil, 1.6 parts of aromatic hydrocarbon resin, 1.6 parts of polycyclopentadiene resin, 2 parts of resorcinol, 1.35 parts of accelerator H, 0.15 parts of accelerator D, 0.8 parts of accelerator NS, 2.1 parts of sulfur; Total 148.2 copies.

30 parts of natural rubber, 30 parts of styrene-butadiene rubber, 40 parts of tire reclaimed rubber, 2.5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant RD, 28 parts of carbon black N550, 7 parts of aromatic hydrocarbon oil, 0.15 parts of accelerator D, 0.55 parts of accelerator DM, 1.9 parts of sulfur; Total 142.1 copies.

3. Natural rubber/isoprene rubber/tire reclaimed rubber and vulcanization formula for the production of radial tire carcass, nylon cord layer rubber

35 parts of natural rubber, 30 parts of isoprene rubber, 35 parts of tire reclaimed rubber, 2.5 parts of zinc oxide, 1 part of stearic acid, 0.5 parts of antioxidant RD, 25 parts of carbon black N550, 8.5 parts of petroleum asphalt, 1 part of accelerator NS, 0.15 parts of accelerator TMTD, 2.55 parts of sulfur; Total 141.2 copies.

Radial tire carcass nylon cord layer adhesive requires the rubber material used to have high elasticity and high strength, as well as good heat resistance, flex resistance, chemical resistance and adhesion. When using tire reclaimed rubber to reduce the production cost of nylon cord layer E4LYY1010 glue, we must comprehensively consider the specific needs of ply layer glue, select tire reclaimed rubber with appropriate indicators, reasonably determine the mixing ratio of tire reclaimed rubber, and appropriately adjust the formula to further optimize the comprehensive performance of nylon cord rubber for radial tire carcass while reducing costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits