Tire reclaimed rubber is made from the rubber portion of waste tires through processes such as crushing, desulfurization, and refining. It has a certain degree of plasticity and stickiness and can be processed and re-vulcanized. It can be re-added to the production of rubber products, such as car tires, rubber hoses, conveyor belts, seals, and shock-absorbing blocks, and is a primary raw material for reducing the production costs of rubber products. How much is tire reclaimed rubber per ton? What factors affect the price of tire reclaimed rubber?

1. Market price of tire reclaimed rubber

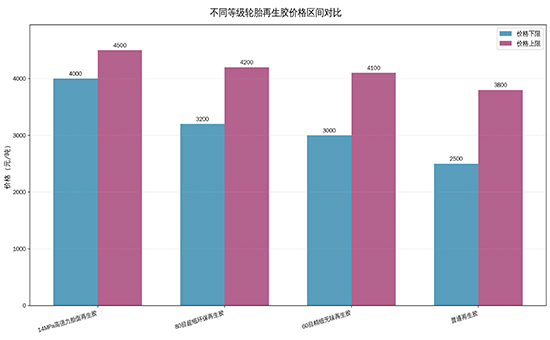

Currently, the price of recycled tire rubber on the market ranges from 2,500 to 5,000 yuan per ton. Its price is directly related to the product's tensile strength, fineness, and environmental standards. The price of tire recycled rubber E5LYY66 varies significantly among different grades and specifications. For recycled tire rubber with the same fineness, the higher the tensile strength, the higher the price; for tire recycled rubber with similar strength, the finer the material, the higher the price; environmentally-friendly recycled tire rubber that meets environmental standards is priced higher than ordinary recycled tire rubber.

The price of 14MPa high-strength tire tread recycled rubber is 4,000-4,500 RMB/ton, 80-mesh ultra-fine environmentally friendly tire recycled rubber is 3,200-4,200 RMB/ton, 60-mesh fine odorless tire recycled rubber is 3,000-4,100 RMB/ton, and ordinary tire recycled rubber is 2,500-3,800 RMB/ton. These prices are recent reference prices for tire recycled rubber, and there are certain differences in tire recycled rubber prices at different times and in different regions.

2. Factors affecting tire recycled rubber prices

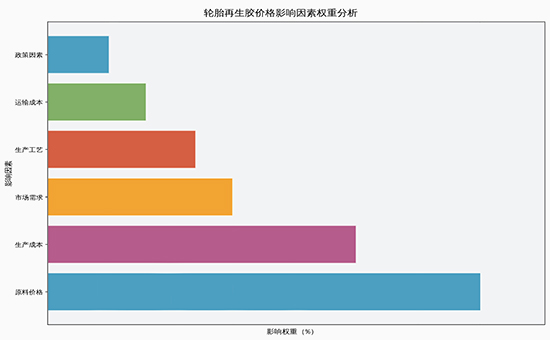

(1) Raw material prices: The production of recycled tire rubber relies on waste tires. Fluctuations in the recycling prices of waste tires will directly affect the cost and price of recycled rubber.

(2) Production costs: The production costs of recycled tire rubber include water bills, electricity bills, equipment depreciation, labor costs, etc., incurred during the production process. An increase in production costs will drive up the price of recycled rubber.

(3) Transportation costs: Transportation fees affect the final price of recycled tire rubber, especially for long-distance transportation. Generally, it is recommended to purchase low-priced recycled tire rubber locally.

(4) Market demand: The supply and demand relationship is a fundamental factor affecting market prices. Changes in the supply and demand of recycled tire rubber directly influence product prices. When the supply of recycled tire rubber exceeds demand, prices may fall; when demand exceeds supply, prices may rise.

(5) Production processes: Different production processes and technical levels can affect the quality and output of recycled rubber, thereby impacting prices. Technological advancements can improve the production efficiency and product quality of recycled rubber, reducing costs.

(6) Policy factors: Government policies on the recycling and utilization of waste tires, as well as environmental protection policies, can affect the production and sales of recycled rubber.

There are many factors that affect the price of recycled tire rubber, but compared to virgin rubber, the price of recycled rubber fluctuates very little. When manufacturers of rubber products use recycled tire rubber, they need to comprehensively consider the performance requirements of the rubber products and the cost budget (including transportation costs) to choose suitable recycled tire rubber, which can reduce more raw material costs while ensuring the quality of rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits