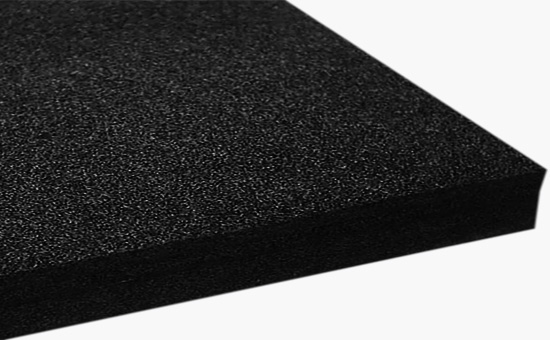

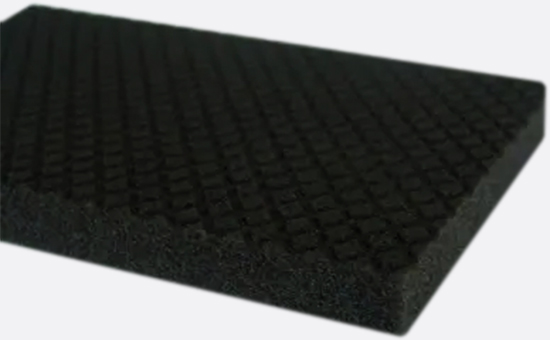

The sponge rubber sheet has low density, good elasticity, and is resistant to flexing. It has obvious effects such as shock absorption, sound insulation, and heat insulation during use, and is widely used in various industries. In raw rubber production, ordinary sponge rubber sheets are generally processed with natural rubber as the main raw material; latex reclaimed rubber, as a low-cost raw material to replace natural rubber, has the characteristics of high strength and good elasticity, and can be used in sponge production; choose appropriate The latex reclaimed rubber and the rational design of the formula of the sponge rubber sheet containing the latex reclaimed rubber can further optimize the performance of the rubber sheet while reducing the cost.

1. Selection skills of latex reclaimed rubber for sponge rubber sheet

When using latex reclaimed rubber instead of natural rubber to produce sponge rubber sheets, black latex reclaimed rubber is recommended for ordinary sponge rubber sheets, and the cost of raw materials is lower; white latex rubber sheets are recommended to use white latex reclaimed rubber 2ELYY71; color sponge rubber sheets can be regenerated with white latex Adhesive or color latex reclaimed rubber of corresponding color, easy to color match, no migration. In addition, when using latex reclaimed rubber to produce indoor sponge rubber sheets, it is recommended to use environmentally friendly latex reclaimed rubber and odorless latex reclaimed rubber that have passed environmental protection certification to avoid harmful substances that endanger human health.

2. Reference formula of sponge rubber sheet mixed with latex reclaimed rubber

(1) The formula of black ordinary sponge rubber sheet mixed with latex reclaimed rubber: 50 parts of natural rubber, 50 parts of 100% black latex reclaimed rubber, 5 parts of zinc oxide, 5 parts of stearic acid, 1 part of antioxidant D, 1 part of paraffin, 80 parts of light calcium, 10 parts of lithopone, 15 parts of white ointment, 10 parts of motor oil, 30 parts of petrolatum, 29 parts of baking soda, 0.9 parts of accelerator D, 1.7 parts of accelerator DM, 3.2 parts of sulfur; total: 291.8 parts .

(2) White sponge rubber sheet product latex reclaimed rubber formula: 50 parts of natural rubber, 50 parts of 100% white latex reclaimed rubber, 5 parts of zinc oxide, 5 parts of stearic acid, 2 parts of paraffin, 40 parts of light calcium, 10 parts of titanium dioxide parts, 8 parts of dibutyl phthalate, 1 part of triethanolamine, 5 parts of foaming agent H, 5 parts of baking soda, 7 parts of vaseline, 2.5 parts of crosslinking agent; total: 190.5 parts.

3. Performance optimization of sponge rubber sheet produced from latex reclaimed rubber

When using latex reclaimed rubber to produce low-cost sponge rubber sheets, rubber product manufacturers need to properly adjust the formula to prepare sulfur and accelerators required for rubber hydrocarbons in vulcanized reclaimed rubber. Compared with natural rubber, the amount of sulfur and accelerators used in the production of sponge rubber sheets from latex reclaimed rubber can be increased by about 20%; the amount of sulfur in sponge rubber sheets containing latex reclaimed rubber is slightly more, and it is not as easy as pure natural rubber. Frost phenomenon.

In actual production, when adjusting the formula to optimize the physical properties and performance of the sponge rubber sheet containing latex reclaimed rubber, it is the most reasonable to replace part of the raw rubber with reclaimed rubber. As follows: When replacing natural rubber with reclaimed rubber, use the effective rubber fraction in natural reclaimed rubber. Later, the editor will continue to share with you the calculation method of the amount of compounding agent in the specific formula of natural rubber/latex reclaimed rubber combined with rubber to produce sponge rubber sheet.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits