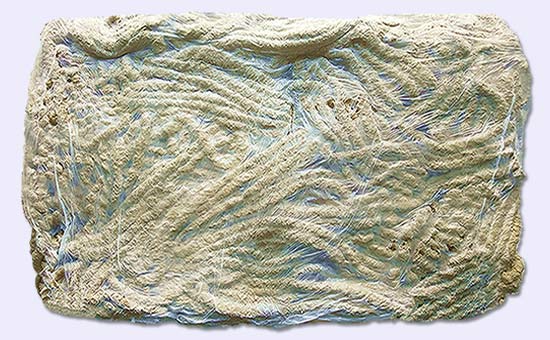

Latex reclaimed rubber is a new type of rubber raw material processed from waste natural rubber, waste latex and products, which has the characteristics of high mechanical strength, good elasticity and high wear resistance, and has good compatibility with natural rubber and general synthetic rubber. When using latex reclaimed rubber to reduce the production cost of rubber shoe compound, the following points need to be noted.

1. What rubber can latex reclaimed rubber replace in rubber shoe compound?

(1) Natural rubber: the main raw material for the production of rubber for rubber shoes. The main component of latex reclaimed rubber is rubber hydrocarbons, which have the basic performance characteristics of natural rubber, and can directly replace natural rubber or be used in combination with it to prepare rubber shoe compounds.

(2) Butadiene rubber: It is polymerized from butadiene, which has excellent cold resistance, wear resistance and elasticity after vulcanization, and is an ideal raw material for the preparation of rubber shoe compounds. Latex reclaimed rubber has good compatibility with butadiene rubber, and can replace part of butadiene rubber to produce rubber for rubber shoes.

2. The advantages of latex reclaimed rubber in the production of rubber shoe rubber

(1) Low price: the price of latex reclaimed rubber is much lower than that of natural rubber and synthetic rubber, which can effectively reduce the cost of raw rubber in the production of rubber shoe rubber, and enable rubber shoe manufacturers to better control costs in the face of raw material price fluctuations.

(2) Good processing performance: latex reclaimed rubber has the characteristics of high plasticity, good fluidity, low power consumption, small vulcanization return, small expansion and contraction of unvulcanized rubber, easy color matching, etc., and natural rubber, butadiene rubber can reduce production energy consumption, improve the size and shape stability of finished products, and reduce the vulcanization and return tendency of natural rubber.

(3) Aging resistance: latex reclaimed rubber has undergone intense treatment such as vulcanization and mixing during processing, and the rubber hydrocarbons have been in a stable state; The combination of natural rubber to produce rubber for rubber shoes can further improve the aging resistance of the finished product.

3. Tips for choosing latex reclaimed rubber for rubber shoes

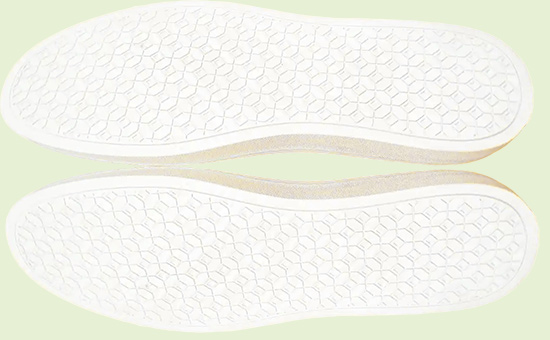

When choosing latex reclaimed rubber for rubber shoes, it is necessary to comprehensively consider the color, appearance, physical and mechanical properties of the rubber material, and the cost budget. It is recommended to choose ultra-fine latex reclaimed rubber for rubber shoes, which can ensure the uniformity and processing performance of the rubber material and reduce the impact of impurities on product quality. It is recommended to use white latex reclaimed rubber for light-colored or colored rubber shoes, which is easy to match and not easy to change color; Black rubber shoes can use black latex reclaimed rubber, which is more cost-effective.

4. Rubber shoes mixed with latex reclaimed rubber formula adjustment skills

The performance of different parts of rubber shoe rubber needs to be different, and the amount of latex reclaimed rubber needs to be reasonably controlled, and the reinforcing filling system, softening system and vulcanization system in the rubber formula need to be appropriately adjusted. Generally, the amount of reclaimed rubber E4LYY614 in the outsole of rubber shoes can be less than the amount of heel of shoes. In the sponge sole, the reasonable mixing of latex reclaimed rubber can improve the starting rate and the appearance stability of the finished product. The use of sodium bicarbonate and foaming agent H can improve the foaming effect of the sponge sole. Cheap fillers such as calcium carbonate and clay are added in an appropriate amount to further reduce the cost of raw materials.

When using latex reclaimed rubber to reduce the production cost of rubber shoe compounds, it is also necessary to appropriately adjust the production process conditions.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits