Odorless latex recycled rubber is processed from waste natural rubber, waste latex and its products as raw materials, with high strength, good elasticity, small specific gravity, tastelessness and other characteristics, which can be used alone or combined with natural rubber and general synthetic rubber to produce stroller tires, effectively reducing the cost of raw materials. How to choose the right odorless latex recycled rubber when using latex recycled rubber to produce stroller tires? What issues should be paid attention to in the production process?

1. Key points for selecting odorless latex recycled rubber for stroller tires

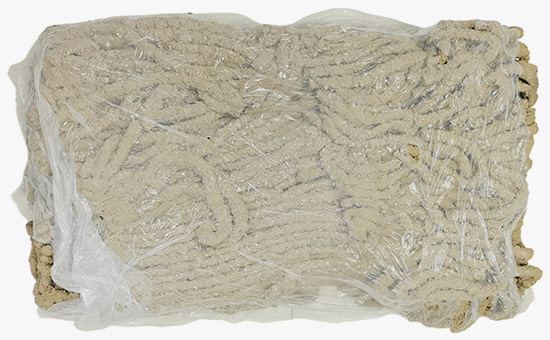

When using latex recycled rubber to produce stroller tires, it is necessary to choose the appropriate index of latex recycled rubber according to the physical and mechanical properties of the tires, and it is recommended to give priority to recycled rubber with high glue content and tensile strength ≥ 12MPa, and the finished stroller tires have better wear resistance and tear resistance; It is recommended to use white latex recycled rubber that does not migrate to light or colored stroller tires, which is easy to match and avoid yellowing during processing or use.

2. Odorless latex recycled rubber production stroller tire formula design

When using odorless latex recycled rubber to produce stroller tires, the sulfur-accelerator system is mostly used, and it is recommended to use accelerators CZ and DM with sulfur, which has low cost, E5LYY730, tasteless, and high vulcanization efficiency. Carbon black uses the most commonly used reinforcement, and light-colored stroller tires can be reinforced with silica, with a small amount of lightweight calcium carbonate; The softening system can use environmentally friendly paraffin oil and naphthenic oil, and the use of polluting softeners such as aromatic hydrocarbon oil and asphalt is prohibited, and the dosage is controlled among 5-10 parts to prevent precipitation. Use 1-3 parts of non-polluting anti-aging agent to inhibit the aging of stroller tires.

3. Latex recycled rubber produces colored stroller tire vulcanization formula

70 parts of odorless white latex recycled glue, 20 parts of natural rubber, 10 parts of butadiene rubber, 3 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of anti-aging agent MB, 0.5 parts of anti-aging agent 2246, 1 part of paraffin, 25 parts of silica, 10 parts of light calcium, 3 parts of titanium dioxide, 2 parts of polyethylene glycol, 5 parts of naphthenic oil, 1.2 parts of accelerator CBS, 0.6 parts of accelerator DM, 0.2 parts of accelerator TMTD, 1.4 parts of sulfur, 3.3 parts of rubber pigment; Total 158.7 copies.

When using odorless latex recycled rubber to produce stroller tires, the mixing ratio of recycled rubber is determined by the physical demand of stroller tires, latex recycled rubber indicators and cost budget. The follow-up editor will share with you the key points of the process of producing stroller tires with odorless latex recycled rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits