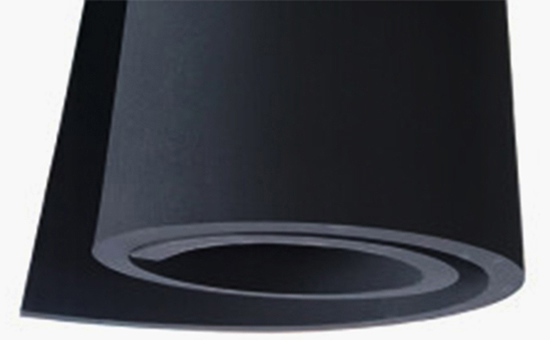

EPDM recycled rubber has excellent high and low temperature resistance, aging resistance, ozone resistance and other properties, and is widely used in the production of various sponge rubber products, such as heat-resistant sponge rubber sheets, sponge sealing strips, etc. When using EPDM reclaimed rubber to produce sponge rubber products, it is necessary to select appropriate rubber and reclaimed rubber raw materials and reasonably design the formula according to the specific performance requirements of the products, such as heat resistance and aging resistance.

1. EPDM reclaimed rubber production sponge rubber vulcanizing agent and foaming agent

When using EPDM reclaimed rubber or EPDM rubber/EPDM reclaimed rubber to produce sponge rubber products, the matching of vulcanization speed and foaming speed is very important: if the foaming speed is too fast, it may lead to insufficient foaming and unsmooth skin; If the rate of vulcanization is too fast, it may cause foaming difficulties. When EPDM recycled rubber is used to prepare sponge compounds, the commonly used vulcanizing agents include sulfur and peroxide, and the commonly used foaming agents include AC, OBSH, etc., as well as their compounds.

When EPDM reclaimed rubber sponge rubber is foamed by continuous extrusion vulcanization, foaming agents AC and OBSH are generally used, as well as foaming agent systems that are compounded with each other or with foaming active agents; Sulfur vulcanization system is adopted. When the sulfur-accelerator system was selected for EPDM reclaimed rubber sponge compound, the foaming agents AC and OBSH had a tendency to delay the vulcanization of the rubber compound, and the foaming agent H had a tendency to promote vulcanization. The accelerator lowers the decomposition temperature of the blowing agent.

When EPDM reclaimed rubber is prepared for continuous vulcanization of extruded sponge rubber, several accelerators can be used at the same time, and ultra-fast accelerators such as accelerators PZ and EZ can be used to make the rubber foam at a suitable viscosity E4LYY610. Since the foaming of sponge rubber is carried out with vulcanization, the vulcanization speed is slightly faster than the foaming speed to maintain the pore wall strength required for foaming, so the foaming process can be controlled by the vulcanization speed: the vulcanization rate of general sponge rubber is 10% faster than that of solid rubber.

2. Key points of the design of sponge rubber reinforcement filling system for the production of EPDM reclaimed rubber

When using EPDM reclaimed rubber as the main raw material to prepare sponge rubber, the design of the reinforcing filling system is very important. it is generally necessary to choose a medium-reinforcing fast-extrusion carbon black, semi-reinforcing carbon black or a combined system of this type of carbon black, such as N774, N770, N660, N550, etc.

EPDM reclaimed rubber sponge glue reinforced with carbon black generally tends to produce large pore structure and rough epidermis, which can be improved by filling inorganic fillers such as calcium carbonate, talcum powder, calcined clay, aluminum silicate, etc.; The inorganic filler recommended to be filled has the characteristics of small particle size, good dispersion in the rubber compound, and low content of impurity particles.

Microwave continuous vulcanization is mostly used in the production of sealing strips with sponge glue and solid rubber composite by EPDM reclaimed rubber, and the use of N550 carbon black with finer particles is conducive to absorbing microwave energy to ensure the balance of energy absorption among solid rubber and sponge glue. Because the reinforcing properties of N550 carbon black are too large, which is not conducive to improving the foaming rate, it is recommended to use fast-pressed carbon black (such as N550) and semi-reinforcing carbon black (such as N774) or low reinforcing carbon black (such as SP5000, N990 carbon black), and the dosage of N550 carbon black is generally controlled within 50 parts.

3. Key points of the design of sponge rubber softening and plasticizing system for the production of EPDM reclaimed rubber

EPDM reclaimed rubber produces sponge rubber, and the softener can effectively reduce the viscosity of the rubber compound, increase the foaming rate, and improve the processing technology performance of the rubber compound. EPDM reclaimed rubber sponge rubber generally chooses paraffin oil with good compatibility; The compatibility and softening effect of petroleum jelly and low molecular weight polyethylene wax are also very good, which can improve the process performance of processing; Vulcanized ointment can improve the stiffness and size retention of low-viscosity sponge glue, and the dosage is generally 10~30 parts.

Petroleum resin can improve the uniformity and processing performance of EPDM reclaimed rubber sponge rubber dispersion, and the general dosage is 2~5 parts; In addition to the softening effect of stearic acid and zinc stearate in sponge glue, it is also an active agent for vulcanization and foaming, and the general dosage is higher than that of solid glue, usually 1.5~4 parts.

Sponge rubber requires the rubber material to have good elasticity, low compression set, wear resistance, heat resistance, tear resistance, aging resistance, smooth extrusion and vulcanized surface crusting, good mixing performance, extrusion performance, good mouth size retention, high dimensional stability, as well as good cell structure, high porosity and good cell uniformity. Therefore, when using EPDM reclaimed rubber or EPDM rubber/reclaimed rubber and glue to prepare sponge rubber materials, the formula must be reasonably designed, and the follow-up editor will share with you the EPDM reclaimed rubber sponge rubber vulcanization formula.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits