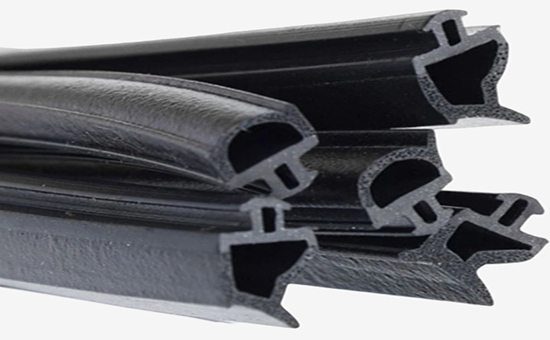

EPDM recycled rubber is processed from EPDM head adhesive, unvulcanized EPDM rubber or waste EPDM rubber sealing strips as raw materials, which has good high and low temperature resistance, ozone resistance and aging resistance, and can replace EPDM raw rubber in whole or in part to produce various rubber products, effectively reducing raw material costs. When using EPDM recycled rubber to produce products, compounding is an important process, so what raw materials need to be prepared before preparing EPDM recycled rubber compounds?

1. Rubber raw materials

(1) EPDM recycled rubber: The main material of EPDM recycled rubber compound rubber needs to be selected according to specific performance requirements (tensile strength, tear elongation, hardness, Mooney, fineness, etc.) to select the appropriate EPDM recycled rubber.

(2) EPDM rubber: When EPDM recycled rubber compound has strict requirements for tensile strength, compression set, etc., EPDM can be mixed with an appropriate amount, and the matching degree of EPDM raw rubber and EPDM recycled rubber Mooney viscosity needs to be considered.

(3) Other varieties of rubber or recycled rubber: When preparing compound rubber, EPDM recycled rubber can also be used in combination with a small amount of butyl rubber, butyl recycled rubber and other rubber materials to improve the aging of EPDM recycled rubber products and extend the service life.

2. Rubber vulcanizing agent and accelerator

In the preparation of EPDM recycled rubber compounds, commonly used vulcanizing agents include sulfur and peroxide (DCP). For EPDM recycled rubber compounds with high mechanical strength requirements, sulfur vulcanization system can be used, and peroxide vulcanization system is recommended when heat resistance requirements are strict. Choose the appropriate vulcanization accelerator and activator according to actual needs, such as accelerator M, accelerator D, accelerator DM, accelerator CZ, accelerator TMTD, zinc oxide, stearic acid, TAIC, etc.

3. Rubber reinforcing agent and filler

The commonly used reinforcing agents of EPDM recycled rubber compounds are carbon black (commonly used carbon black N330, N550, N660, N774, etc.), silica, and fillers include calcium carbonate, clay, talc, etc., to improve the mechanical strength of EPDM recycled rubber compounds and improve the performance of rubber processing technology. When using EPDM recycled rubber to prepare flame retardant rubber products, it is also necessary to use aluminum hydroxide or magnesium hydroxide.

4. Rubber softening plasticizer and operation aid

The commonly used rubber oils for EPDM recycled rubber compounds include paraffin oil, naphthenic oil and aromatic oil, paraffin oil is the most suitable, and coumallon resin, pine tar, esters and low molecular weight polymers can also be used. When there is silica in the formula of EPDM recycled adhesive compound, it is recommended to use an appropriate amount of silane coupling agent; Operating aids include hygroscopic agents (calcium oxide and its dispersions, etc.), viscosity enhancers, release agents, dispersants, flow agents, etc.

5. Rubber anti-aging agent

EPDM recycled rubber itself has good aging resistance, generally does not use anti-aging agents, and can be used with 0.5-1 anti-aging agents when necessary, especially rubber products used under high temperature conditions.

When preparing compound rubber with EPDM recycled rubber as the main raw material, it is not only necessary to select the appropriate variety of rubber raw materials and rubber additives according to actual needs, but also to process the compound and compound E5LYY716 in advance, such as powder compounding agents (sulfur, accelerator, carbon black, etc.) for granulation, etc., preheating the softener, and supplementing the materials whose quality does not meet the specific use requirements (such as drying, crushing, screening, etc.), and continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits