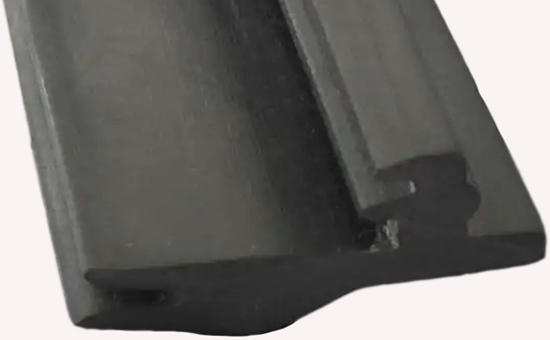

Oil resistant rubber sealing strip is exposed to oil medium for a long time. In order to avoid swelling of the sealing strip and affect the sealing effect, nitrile rubber with excellent oil resistance performance is often used or used together with neoprene. The reclaimed butadiene acrylonitrile rubber retains the basic performance characteristics of the original butadiene acrylonitrile rubber, and has a large oil resistance coefficient. It can directly replace the appropriate proportion of butadiene acrylonitrile rubber to produce oil resistant rubber seals; Reasonable design of the formulation of oil resistant sealing strip containing reclaimed butadiene acrylonitrile rubber can further optimize the product quality while reducing the cost.

1. Application mode of nitrile reclaimed rubber in oil resistant rubber sealing strip

The requirements for technical indicators of oil resistant rubber seals in different applications are different, and the indicators of different nitrile reclaimed rubber products are also different, so the application methods of nitrile reclaimed rubber in oil resistant seals are different. In general, nitrile rubber 2ELYY129 can be used alone or together with nitrile rubber to produce rubber sealing strips; The reclaimed nitrile rubber can also be blended with neoprene or NBR/reclaimed nitrile rubber/neoprene to prepare oil resistant sealing strips.

2. Key points of design for matching system of oil resistant sealing strip produced by nitrile reclaimed rubber

In actual production, in addition to excellent oil resistance, the rubber compound used for oil resistant rubber sealing strip also needs to have good processing safety, low Mooney viscosity, no frost spraying, small discoloration, and good tensile strength and compression resistance.

When the oil resistant rubber sealing strip is mixed with nitrile reclaimed rubber to reduce the cost, the sulfur accelerator system is often used. Accelerator M, accelerator D, accelerator DM, and accelerator TMTD can be mixed with one or more kinds of sulfur, and zinc oxide (or active zinc oxide) can be mixed with stearic acid. In consideration of the appearance quality and extrusion process performance of rubber sealing strips, ointment, polymer wax, modified plastics, etc. can give good stiffness and deformation resistance to the rubber compound; The use of ointment, mineral oil, clay and stearic acid can improve the extrusion speed of semi-finished products and keep them smooth.

3. Formula of oil resistant sealing strip produced by nitrile rubber/reclaimed nitrile rubber

80 for nitrile rubber, 20 for nitrile reclaimed rubber, 4.8 for zinc oxide, 1 for stearic acid, 1 for antioxidant A, 50 for carbon black N774, 69 for light calcium, 15 for DBP, 5 for mineral oil, 0.3 for accelerator D, 1.3 for accelerator DM, and 2 for sulfur; Total: 249.4 copies.

In actual production, the oil resistant rubber sealing strip can not only use nitrile reclaimed rubber to reduce costs, but also can be appropriately mixed with neoprene reclaimed rubber. Later, Xiaobian will continue to share with you the key points and precautions of the oil resistant rubber sealing strip production process.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits