Oil-resistant and anti-corrosion rubber products need to resist both oil media and chemical corrosion, such as mineral oil, fuel oil, acid and alkali salt solutions, etc. Nitrile rubber is made of acrylonitrile and butadiene monomer, with excellent oil resistance, good wear resistance, heat resistance, and aging resistance, and is an ideal raw material for the production of oil-resistant and anti-corrosion rubber products. Appropriate amount of recycled glue can effectively reduce the cost of raw materials; Rational design of nitrile oil-resistant and anti-corrosion rubber product formulas containing recycled rubber can further optimize the quality of finished products.

1. Nitrile rubber/recycled rubber is used to produce oil-resistant and anti-corrosion rubber product formulas

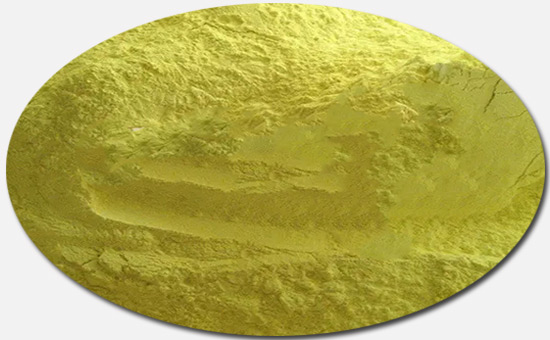

55 parts of nitrile rubber, 45 parts of recycled rubber, 5 parts of zinc oxide, 1 part of stearic acid, 2.5 parts of anti-aging agent A, 3.5 parts of anti-aging agent D, 2 parts of anti-aging agent KY-405, 4.5 parts of barium sulfate, 48 parts of carbon black N774, 2 parts of plasticizer, 0.9 parts of vulcanizing agent, 1.3 parts of accelerator TMTD, 0.15 parts of anti-scorching agent CTP, 0.15 parts of potassium stearate; A total of 171 copies.

2. Selection skills for recycled rubber products for oil-resistant and anti-corrosion rubber products

When using nitrile rubber and recycled rubber together to produce oil-resistant and anti-corrosion rubber products, it is necessary to combine the oil resistance and anti-corrosion performance requirements of rubber products to choose the appropriate recycled rubber.Nitrile recycled rubber retains the basic performance characteristics of nitrile rubber, has a large oil resistance coefficient, and can be used in an appropriate proportion with nitrile rubber to produce oil-resistant and anti-corrosion rubber products, which is suitable for the production of oil-resistant and anti-corrosion rubber products with strict requirements for oil resistance. Nitrile rubber can also be used in conjunction with neoprene recycled rubber and tire recycled rubber to reasonably control the amount of recycled rubber, and the finished product has good oil resistance and corrosion resistance.

3. Key points of formula design of oil-resistant and anti-corrosion rubber products mixed with recycled rubber

(1) Vulcanization system

When producing oil-resistant and anti-corrosion rubber products with nitrile rubber/recycled rubber, sulfur vulcanization system or peroxide (commonly used DCP) vulcanization system can be used, or peroxide-sulfur/accelerator composite vulcanization system can be used, and the commonly used accelerators are DM, CZ, TMTD; Appropriately increase the cross-linking density to improve the oil resistance of nitrile rubber/recycled rubber vulcanized rubber; The rubber with peroxide vulcanization has better compression set resistance and aging resistance.

(2) Filling system

When nitrile rubber and recycled rubber are used together to produce oil-resistant and anti-corrosion rubber products, appropriately increasing the amount of filler can improve the oil resistance of the rubber to a certain extent and reduce the volume change rate. The stronger the E5LYY414 bond among the filler and the rubber with higher activity, the smaller the volume swelling rate of nitrile rubber/recycled rubber vulcanized rubber. For oil-resistant and anti-corrosion rubber with high requirements for compression set deformation, it is recommended to choose fillers with large particles and low activity, and appropriately increase the filling amount; Avoid using fillers that are water-soluble or have a high water content.

(3) Plasticization system

Ester plasticizers are easy to be extracted, and nitrile rubber/recycled rubber should be avoided or used as little as possible when producing oil-resistant and anti-corrosion rubber products, and commonly used plasticizers include coumarone resin, liquid nitrile rubber, polyester and other plasticizers.

When using nitrile rubber/recycled rubber and using rubber to produce oil-resistant and anti-corrosion rubber products, it is not only necessary to reasonably design the rubber product formula, but also to appropriately adjust the production process conditions, and then discuss related issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits