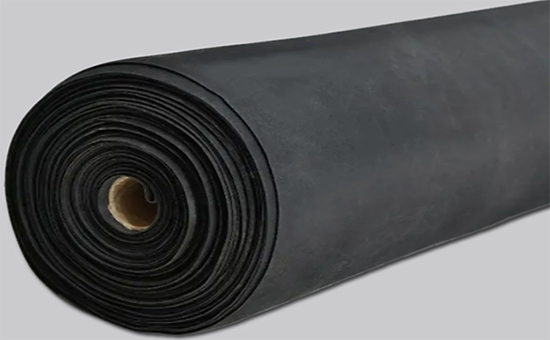

The non-vulcanized waterproof membrane is made of rubber or a blend of rubber and asphalt by mixing and calendering, and does not need to be vulcanized. The production process is simple and the price is low. It can be used for roof waterproofing of civil buildings. The butyl reclaimed rubber processed from waste butyl rubber inner tube or water tire and bladder as raw materials has good air tightness, water resistance, heat resistance and corrosion resistance, and can be used in the production of non-vulcanized waterproof membrane, effectively reducing the cost of raw materials, There are mainly two specific application methods as follows.

1. Use butyl reclaimed rubber alone to produce non-vulcanized waterproof membrane

When using butyl reclaimed rubber alone to produce non-vulcanized waterproofing membranes, the reclaimed rubber can be thinned several times on the open mill, add 1%-2% accelerator, and add compounding agents according to the formula after mixing evenly; After being calendered or extruded into sheets, it can be rolled.

Formula 1: 100 parts of butyl inner tube reclaimed rubber, 100-150 parts of clay, 3 parts of stearic acid, 15-20 parts of softener.

Formulation 2: 100 parts of butyl capsule reclaimed rubber, 2 parts of antioxidant, 6 parts of softener, and 65 parts of filler.

Production process: The waste butyl rubber is plasticized and regenerated by mechanical method on the open mill, and then various compounding agents are added for mixing. Under normal circumstances, the finished non-vulcanized butyl reclaimed rubber 2ELYY318 waterproofing membrane can be divided into three specifications according to thickness, 1.2mm, 1.5mm and 2mm.

2. Butyl reclaimed rubber/asphalt blend to produce non-vulcanized waterproofing membrane

Formula: 30 parts of butyl reclaimed rubber, 50 parts of filler, 20 parts of petroleum asphalt.

Butyl reclaimed rubber can not only be used alone in the preparation of non-vulcanized waterproofing membranes, but also can be blended with asphalt. Butyl reclaimed rubber/asphalt non-vulcanized waterproofing membrane has the characteristics of high elongation, no flow, no foam, no stickiness, no cracks, no water permeability during use.

Waterproofing membrane is an important functional material required in the construction industry and other related industries, with EPDM rubber and butyl rubber as the main raw materials. However, some of my country's EPDM and IIR rubbers still rely on imports, resulting in high manufacturing costs for waterproofing membranes. As a low-cost raw material to replace butyl rubber, butyl reclaimed rubber is used in the production of waterproof membranes to not only ensure the performance of waterproof membranes, but also effectively reduce raw material costs and production costs.

In actual production, when reclaimed rubber/asphalt is blended to prepare waterproof membrane, not only butyl reclaimed rubber, but also ordinary tire reclaimed rubber can be used, which can reduce more raw material costs under the premise of ensuring product performance. I have the opportunity to discuss related issues with you again.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits