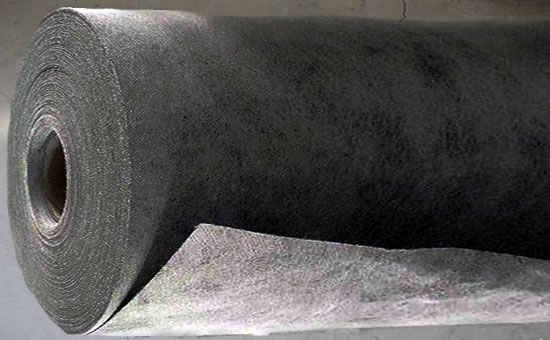

Butyl reclaimed rubber is a new material obtained by recycling and reprocessing waste butyl tubes, capsules and other rubber products, which has similar physical and chemical properties to the original butyl rubber, butyl recycled rubber has vulcanization properties, tensile strength and heat resistance and other characteristics determine suitable for the production of self-adhesive tape or waterproof membrane products. Self-adhesive tape waterproofing membrane has a wide range of applications in construction, engineering and household fields; Therefore, adjusting the proportion of butyl recycled rubber in the formula and the processing technology can reduce costs under the premise of ensuring quality, and the performance of butyl recycled rubber and the process points of producing waterproof membrane self-adhesive tape are detailed below.

First, the performance and characteristics of butyl regenerated rubber

Vulcanization performance: The vulcanization performance of butyl regenerated rubber refers to its crosslinking ability and vulcanization speed in the vulcanization process. Vulcanization is the heating of rubber materials and reaction with vulcanizing agents to form a cross-linked structure, thereby improving the strength and durability of rubber. The vulcanization properties of butyl regenerated rubber are affected by the recycled material, which may contain impurities or aging products that may affect the vulcanization reaction. Therefore, when using butyl regenerated rubber, it is necessary to select appropriate vulcanization conditions and vulcanizing agents to ensure that its vulcanization performance meets the expected requirements (vulcanization reaction is not required in the self-adhesive tape) The vulcanization system used in the production of butyl regenerated rubber is basically divided into sulfur vulcanization system, quinone vulcanization system and resin vulcanization system, can not be vulcanized with peroxide vulcanization system, otherwise it can cause the cracking sulfur vulcanization system of butyl regenerated rubber can obtain processing technology performance and vulcanization rubber performance and other comprehensive performance of the rubber material; The use of quinone vulcanization system can obtain fast, dense vulcanization and vulcanization rubber with excellent heat resistance and ozone resistance; The use of resin vulcanization system can obtain good high temperature resistance.

Tensile strength: The tensile strength of butyl reclaimed rubber refers to the maximum stress it can withstand during the stretching process. Tensile strength is an important indicator to measure the tensile resistance of rubber materials, and it is especially important for self-adhesive tape waterproofing membranes. The tensile strength of butyl recycled rubber is affected by the recycled material, and if the recycled material has a high content of impurities, it may cause the rubber chain to break or be damaged, thereby reducing the tensile strength. When using butyl reclaimed rubber to prepare self-adhesive tape waterproof membrane, it is necessary to choose a filter-type butyl reclaimed rubber, if it cannot meet the strong demand, part of the butyl raw rubber and carbon black can be appropriately added to improve the tensile strength.

Heat resistance: The heat resistance of butyl reclaimed rubber D25M6YY23 refers to its stability and performance in high temperature environment, which can be used in outdoor environment for a long time, and is not easy to be affected by ultraviolet rays, oxygen, etc.

Second, butyl reclaimed rubber production of self-adhesive tape waterproof membrane formula and process:

Butyl regenerated gum 40kg, N550 carbon black 1.5kg, filler 35kg, paraffin oil or aromatic oil 7.5kg, magnesium oxide 3kg, phenolic resin 2.5kg

1. Selection of butyl regenerated rubber: choose butyl reclaimed rubber with good vulcanization performance, tensile strength and heat resistance. The appropriate material can be selected by testing the physical and chemical properties of different butyl reclaimed adhesives.

2. Formula design: according to the requirements of self-adhesive tape waterproof membrane, determine the formula ratio of butyl recycled rubber. Often other additives such as tackifiers, plasticizers, fillers, etc. are also included in the formulation to improve the performance of the material.

3. Processing: Mix butyl regenerated rubber with other formula raw materials and carry out heat processing. Processing methods can include compounding, extrusion, calendering, etc. to obtain the desired shape and performance.

Through the above formula and processing technology, we can obtain stable quality, excellent performance of self-adhesive tape waterproof membrane, the formula and process has been trial-produced in many enterprises and achieved good results, compared with butyl rubber formula cost range of more than 20%. It is expected that more companies will adopt this technology in the future to promote the wide application of butyl recycled rubber production of self-adhesive tape waterproofing membrane. The successful development of the formula and process of butyl recycled rubber production of self-adhesive tape waterproofing membrane has brought new development opportunities to the rubber industry. The application of this innovative technology will reduce production costs, protect environmental resources and promote the sustainable development of the rubber industry. It is believed that in the near future, the self-adhesive tape waterproofing membrane produced by butyl recycled rubber will become the mainstream product of the rubber industry.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits