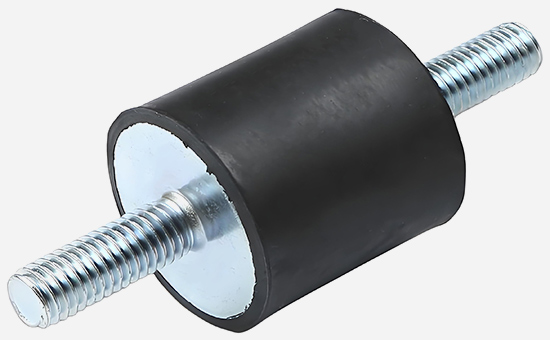

The engine shock absorber is a key component connecting the engine with the body or chassis, and its main function is to use its own elastic deformation to absorb and isolate the vibration and noise generated by the engine when it is running. Rubber engine shock absorbers are generally processed from natural rubber, ethylene propylene rubber, butyl rubber, chlorobutyl rubber, etc.; The appropriate amount of butyl reclaimed rubber can effectively reduce the production cost of rubber engine shock absorbers.

1. Performance requirements for rubber engine shock absorbers

The engine shock absorber uses its own elastic deformation to absorb the vibration generated by the engine, so that the vibration of the engine is transmitted to the chassis as little as possible. The engine shock absorber produced with rubber as the main raw material has the characteristics of light weight, good elasticity, wear resistance and strong absorption capacity, and the rubber used requires good shock absorption performance, sufficient mechanical strength and durability, suitable elasticity and stiffness, and high damping performance.

2. The rubber engine shock absorber is mixed with butyl reclaimed rubber vulcanization formula

(1) 80 parts of butyl rubber, 20 parts of butyl reclaimed rubber, 5 parts of zinc oxide, 48 parts of carbon black N330, 10 parts of naphthenic oil, 2 parts of accelerator CED, 0.5 parts of accelerator DM, 1.5 parts of sulfur; A total of 167 copies.

(2) 70 parts of butyl rubber, 30 parts of butyl reclaimed rubber, 5 parts of zinc oxide, 45 parts of carbon black N330, 21 parts of naphthenic oil, 2 parts of accelerator CED, 0.5 parts of accelerator DM, 1.7 parts of sulfur; Total 175.2 copies.

(3) 60 parts of butyl rubber, 20 parts of EPDM rubber, 20 parts of butyl reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 45 parts of carbon black N330, 20 parts of carbon black N990, 32 parts of naphthenic oil, 0.4 parts of accelerator M, 1.2 parts of accelerator TMTD, 1.2 parts of sulfur; Total 205.8 copies.

3. The rubber engine shock absorber is mixed with butyl reclaimed rubber formula design

(1) Butyl reclaimed rubber in rubber engine shock absorbers

Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, has good air tightness, heat resistance and damping, and can be used with butyl rubber, chlorinated butyl rubber, EPDM rubber, etc. to produce automobile engine shock absorbers, effectively reduce the cost of raw materials, and improve the performance of rubber processing technology.

(2) The design of the vulcanization system of the engine shock absorber mixed with butyl reclaimed rubber

The vulcanization system has a great influence on the stiffness, damping coefficient, heat resistance and fatigue resistance of the rubber shock absorber, and the higher vulcanization density is helpful to improve the damping effect.

When butyl rubber and butyl reclaimed rubber are used together to produce engine shock absorbers, sulfur accelerator system or sulfur vulcanization system is commonly used. According to the steric resistance effect of the accelerator itself, the rubber compound with accelerator DZ has the lowest rebound value, the largest energy loss, and better damping performance. The rubber compound with accelerator M has the largest rebound value, the smallest energy loss, and the worst damping performance. After aging, the rubber compound with DZ/CZ is added, and the resilience increases under the heating conditions of high temperature and long-term heating, and the thermal stability of DZ/CZ is poor.

(3) The engine shock absorber is mixed with butyl reclaimed rubber to reinforce the filling system design

The compounding agent of the rubber reinforcing filling system is the most significant factor affecting the dynamic damping characteristics of the rubber compound except for rubber, which is closely related to the damping coefficient and modulus of vulcanization.

Carbon black is the most commonly used reinforcing agent in engine shock absorbers, the smaller the particle size, the larger the specific surface area, and the tighter the combination with the rubber molecular chain, the more significant the reinforcing effect. Small particle size carbon black will lead to increased hysteresis loss of rubber E5LYY13; The specific surface area of large-particle soft carbon black is small, and the reinforcing effect is weak, but the elastic modulus is moderate and the resilience is high, which can reduce the hysteresis loss, and is suitable for the production of engine shock absorbers. The mica powder treated with silane coupling agent is effective in widening the damping temperature and frequency range of butyl rubber.

When using butyl reclaimed rubber to reduce the production cost of rubber engine shock absorbers, it is necessary to select the appropriate butyl reclaimed rubber according to the actual needs, reasonably determine the mixing ratio of butyl reclaimed rubber, and adjust the physical properties of the shock absorber rubber by adjusting the variety and dosage of vulcanizing agent, accelerator, reinforcing agent, filler and other compounding agents in the formula, so as to meet the performance requirements of more engine shock absorbers and reduce more raw material costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits