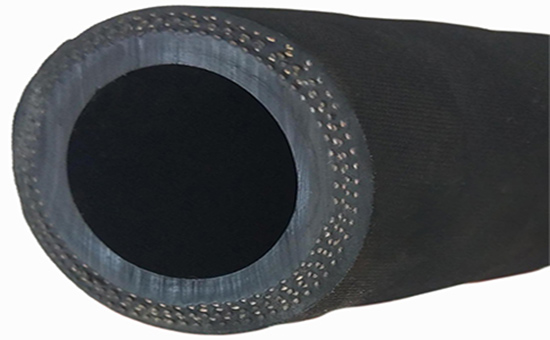

Tensile stress is an important index to characterize the rigidity of rubber materials, which refers to the load per unit cross-sectional area that needs to be applied to make the specimen reach a given elongation during the tensile process. High tensile stress rubber products provide better abrasion resistance, tear resistance, and overall performance. When using reclaimed rubber to produce rubber tires, sealing strips, sealing rings, shock absorbers, conveyor belts, rubber pipes, rubber rollers and other products, the rubber material is required to have a high tensile stress, how to design the recycled rubber formula?

1. High tensile stress recycled rubber formula raw rubber selection

When using reclaimed rubber as the main raw material to prepare high tensile stress rubber compound, it can be used in combination with a small amount of rubber with high molecular weight, high polarity and high crystallinity, such as natural rubber, neoprene, nitrile rubber, etc. Natural rubber can produce crystallization when stretched, thereby increasing the intermolecular force, which can effectively improve the tensile stress of reclaimed rubber. The intermolecular force of rubber with polar atoms or groups is large, and the combination of reclaimed rubber and it can also improve the tensile stress of the rubber compound.

2. Design of vulcanization system for high tensile stress recycled rubber formula

When using reclaimed rubber to produce rubber products with high requirements for tensile stress, the design of the vulcanization system is very important. The tensile stress of reclaimed rubber vulcanized rubber is closely related to the vulcanization cross-linking density and vulcanization cross-linking bond type.

Appropriately increasing the degree of vulcanization and increasing the cross-linking density can effectively improve the tensile stress of vulcanized rubber. In actual production, the crosslinking density can be adjusted by adjusting the dosage of vulcanizing agent, accelerator, active agent and other compounding agents in the vulcanization system of reclaimed rubber E4LYY423 which can be adjusted. Generally, accelerators with high activity, such as thiuram, guanidine and hyposulfonamide accelerators, can improve the tensile stress of rubber compounds; The accelerator TMTD has multiple functions of activation, accelerator and vulcanization, and the use of TMTD can effectively improve the tensile stress of reclaimed rubber.

The tensile stress of the vulcanized rubber is related to the type of vulcanized cross-linked bond, generally the vulcanized rubber dominated by -C-C-cross-linked bond increases rapidly, while the vulcanized rubber dominated by polysulfide bond grows slowly. When designing the recycled rubber formulation, when it is necessary to reduce the content of polysulfide bonds and reduce the amount of sulfur, the amount of accelerator should be increased appropriately to keep the constant tensile stress of vulcanized rubber; The product of sulfur and accelerator dosage is kept constant.

3. Design of high tensile stress recycled rubber formula filler system

When reclaimed rubber is prepared with high tensile stress, the variety, dosage and characteristics of the filler have a significant impact on the tensile stress of vulcanized rubber. In fact, the addition of filler can increase the rigidity of the rubber, which in turn increases the tensile stress. Choosing fillers with small particle size, high activity and high structure, such as carbon black, can significantly improve the tensile stress of reclaimed rubber; In the case of the same amount of carbon black, the influence of structural properties on tensile stress is more significant.

When using reclaimed rubber to produce rubber products that require high tensile stress, we must choose the right raw rubber and compounding agent, especially the vulcanization system compounding agent, reinforcing agent and filler.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits